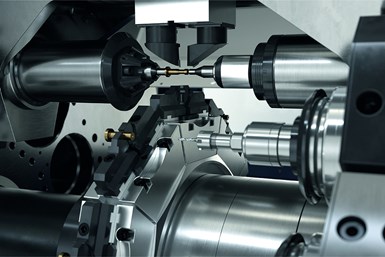

Independent Turning Cell Enables High Concentricity Precision

PMTS 2023: The RV 10 Flexmaster rotary transfer machine’s precision turning cell (PTC) is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations.

#PMTS

Edited by Angela Osborne

Winema says its precision turning cell (PTC) within its RV 10 Flexmaster rotary transfer machine enables users to machine the entire external contour of a workpiece without positioning errors, accurate to a micron level. The robust PTC is integrated in the machine as a disconnected turning cell and is free of the drive and machining factors that affect the other stations. With the PTC, the company says users can achieve the highest levels of concentricity precision with internal and external turning.

As a closed, internally rigid design, the PTC can transfer the workpiece into an independent coordinate system where it can conduct a turning process in isolation. The vibration-damped cast design disconnects the turning process from the machining factors that affect the other stations. By turning between tips, concentricity requirements that used to be critical can be manufactured without any problem down the entire length of the workpiece.

If the workpiece is held in a collet chuck by the PTC, tight positional tolerances can also be maintained between external and internal contours, all within a reliable process context. Two turning tools with Capto interface are integrated in every PTC. Three PTCs can be used in each RV10 Flexmaster. This offers users the advantage of fast rotary transfer with the possibilities of an automatic lathe — combined in one machine.

The PTC features a vibration-proofed cast construction. It offers the benefits of complete machining of outer contour; internal operations as well; and highest concentricity when turning between centers.

RELATED CONTENT

-

A Different Kind of Machining Center

If one horizontal machining center is good, then three on a single platform should be better, right? That’s the thinking behind the Multicenter concept from Italian builder, Porta Solutions. It blends the volume production capabilities of rotary transfer technology with the flexibility of a machining center in a single platform.

-

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

-

Rotary Transfer Offers Full OD Turning Between Centers

This small-footprint trunnion rotary transfer machine includes an isolated cell to perform full OD turning between centers for improved concentricity compared to flipping parts in a station for backside turning or moving the part to another clamping position.