Integrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

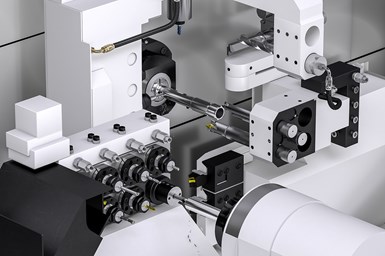

SolidCAM’s MultiChannel Mill-Turn and Swiss-Type CAM solution provides fast and easy programming, high funtionality and full tool-path control to improve manufacturing efficiencies. The solution is designed to offer increased speed and efficiency due to its advanced multichannel synchronization and simulation, and customized tool table for Swiss.

The company has evolved its integrated CAD/CAM software to provide a CAM solution for all CNCs, including multi-axis, advanced mill-turn and Swiss-type. The tool table, real-view multichannel simulator and intelligent iMachining toolpath generator all drive and protect even the smallest tools effectively on advanced CNC machines.

The program offers combined visualization and simplified programming for even the most sophisticated CNC machines. In addition, tool management and advanced machine simulations create an improved user experience for CNC programmers.

SolidCAM also provides machine simulations and postprocessors for all Swiss CNC brands. The software includes iMachining technology for faster cycle times and longer tool life on more conventional CNC machines. The iMachining Technology Wizard provides automatically optimized feeds and speeds based on material, tool and CNC machine parameters. The iMachining Wizard ensures constant tool load at all points of the tool path by varying the cutting angles and feeds.

“SolidCAM can help precision machining manufacturers stay competitive in today's fast-paced manufacturing environment,” says Dr Emil Somekh, CEO of SolidCAM. “Our powerful software is easy-to-learn and use and is seamlessly integrated and associative to SolidWorks and Inventor. Manufacturers will start seeing the benefits immediately. SolidCAM’s technical and post processor staff worldwide provide the best support to its CNC machine shop customers.”

Related Content

-

CAM Software’s Place Serving Emerging Trends

SolidCAM aims to align its product development and customer engagement strategies to address the evolving needs and challenges of the manufacturing industry.

-

Who Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

-

Precision Machining Technology Review: November 2025

Production Machining’s November 2025 technology showcase includes some of the latest technology from Mazak, Platinum Tooling, Methods Machine Tools, Tormach Inc. and Verisurf.