Shotless Cavitation Water Jet Peening Technology

IMTS 2022: Sugino’s shotless water jet peening is well suited for medical devices that need the benefits of shot peening without the contamination of traditional peening media.

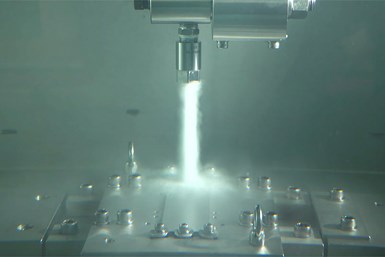

Sugino’s special cavitation promoting nozzle creates GPa class impact force Photo Credit: Sugino Corp.

Sugino’s cavitation water jet peening technology is a shotless peening process that uses only water. It is available with four-axis CNC control for targeted peening that doesn’t require masking and is said to deliver results without waste, safety hazards or extensive cleanup, the company says.

The company says its cavitation-promoting nozzle applies compressive stress to a depth of about 1 mm, achieved through the impact of GPa class force. The cavitation water jet peening is said to deliver increased fatigue strength, longer life and a cleaner finished product.

The process has delivered results on titanium alloy additive and 3D printed parts, specifically those using Ti-6AL-4V powder, the company says. It’s well suited for medical devices that need the benefits of shot peening without the contamination of traditional peening media. It is said this focused technology is able to peen inside holes, tubes and cavities, and uses only water, requiring no additional cleaning processes.

RELATED CONTENT

-

The Importance of Drying Parts After Cleaning

Most cleaning processes consist of three steps, not two: wash, rinse and dry. That drying step is absolutely necessary for everything from product finishing to product performance to effective throughput to product quality.

-

Heat’s Impact on Parts Cleaning

Thermal dynamics is important for assisting in the cleaning of a part. Adding heat or energy influences the cleaning process through its impact on chemistry, the water within the washer and its effect on drying.

-

Automated Cleaning System Improves Productivity

This rotary basket washer drastically reduced the number of operators tending to the cleaning process as well as removed the bottleneck from that station.