Tsugami System Combines Swiss-Style Lathe and Laser Cutter

Tsugami/Rem Sales presents the SS38MH-5AX and LaserSwiss machines.

Tsugami/Rem Sales’ SS38MH-5AX is a 38 mm chucker-convertible, B-axis sliding headstock CNC lathe that performs five-axis machining. This machine features a 40-tool magazine, 10 tools on the back tool post and an optional two-tools on the deep-hole drill holder as well as linear glass scales on the X1-, Y1-, Z1- and X2-axis slides. It is a Swiss-type machine that is said to exhibit the benefits of a turn/mill machine and boasts a Capto C4 automatic tool changer, according to the company. The machine’s backworking overlap with live tool is also said to enable the use of multiple tools in the cut and shorter cycle times.

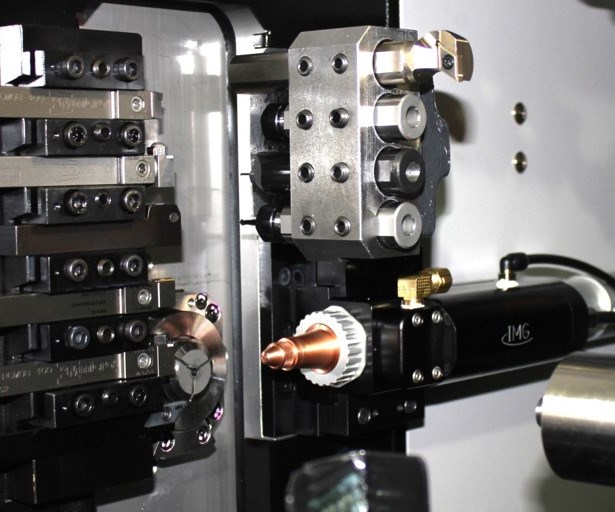

Additionally, the company’s B0205-III LaserSwiss is a 20-mm, five-axis Swiss-turn with an integrated laser cutting system. The machine combines Swiss-style machining with laser cutting on one machining, enabling both operations with a single setup. All operations are programmed and driven by the machine’s FANUC control. It features 10 tool positions in addition to the laser and is convertible between a traditional Swiss-style lathe using a guide bushing or operated with an optional chucker kit.

Related Content

-

Moldmaker Finds Value in Swiss-Type Machining

This multifaceted manufacturer has added CNC sliding-headstock turning technology to complement its established mold tooling production and new injection molding capabilities as it continues to pursue complex medical work along a vertically integrated path.

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.