Verisurf Ultrasonic Thickness Inspection Enhances Renishaw RUP1 Probe

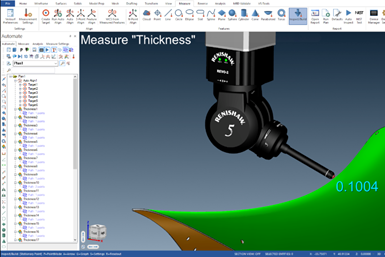

Utilizing Verisurf’s Inspection Plans dynamic surface points tool creates automatic ultrasonic thickness measurements which are stored and presented through a graphical balloon, providing report users with an easy-to-read thickness map associated with the inspected component.

Verisurf’s Inspection Plans dynamic surface points tool creates automatic ultrasonic thickness measurements. Photo Credit: Verisurf Software

Verisurf Software is supporting the Renishaw RUP1 (REVO Ultrasonic Probe) by providing an ultrasonic thickness probing solution to automate the measurement and reporting of thickness requirements. Support for the RUP1 will be featured in the upcoming Verisurf 2024 release.

Utilizing Verisurf’s Inspection Plans dynamic surface points tool enables users to create automatic ultrasonic thickness measurements. These measurements are stored and presented through a graphical balloon, providing recipients of the report with an easy-to-read thickness map associated with the inspected component.

With the RUP1, thickness evaluation is possible for typical metal parts ranging from 1 mm (.039") to 20 mm (.787") in thickness, with an accuracy of .01 mm (.0004") on parallel surfaces and .100 mm (.0039") on wedged surfaces with an angle of up to 10 degrees.

Verisurf Software operates Renishaw-equipped CNC CMMs through the Verisurf Device Interface (VDI), facilitating seamless communication with a wide range of 3D measurement devices. The VDI empowers customers to select their preferred devices while offering a standardized solution that supports design, tolerancing, validation, machining, assembly, measurement, inspection planning, reporting, analysis and reverse engineering.

“Verisurf has been a long-standing supporter of Renishaw-equipped CMMs and standalone Renishaw products, and our team remains dedicated to continually adding value through our software solutions, manufacturing expertise and engineering experience,” says Nick Merrell, executive vice president of Verisurf Software. “Verisurf solutions are renowned for their user-friendliness, stability, flexibility and intelligent workflows, which enhance efficiency, quality and throughput,".

The company says Verisurf is the only measurement, reverse engineering and inspection software built on a full-featured 3D CAD/CAM platform with intelligent Model-Based Definition (MBD). This ensures data integrity and enables users to perform metrology workflows in a seamless CAD environment while maintaining model-based digital continuity.

Verisurf software is compatible with all CAD file formats and the VDI communicates with all 3D measurement devices for universal compatibility. Verisurf’s modular design enables users to quickly shift from reverse engineering to inspection to tool building, efficiently capturing and processing measurement data for all 3D metrology applications with repeatable process control across the manufacturing enterprise.

Related Content

-

Precision Machining Technology Review: July 2025

Production Machining’s July 2025 technology showcase includes some of the latest technology from Hexagon Manufacturing Intelligence, Caron Engineering, Sunnen Products Co., Mastercam, Sandvik Coromant and Kennametal.

-

Does a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

-

Why Not Lights-Out Inspection?

Consider a process to enable your CMM to inspect multiple parts unattended, thereby minimizing the impact that part measurement has on your company’s bottom line.