Walter Tiger-tec Gold Inserts for Tough Steel Turning Applications

A highly textured MT-TiCN layer is said to reduce flank face wear and increases toughness due to its multilayered elastic structure.

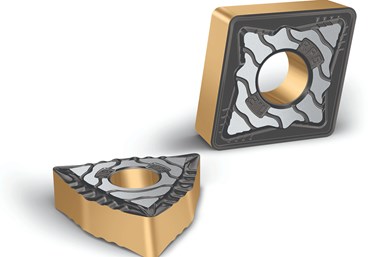

Walter Tiger·tec Gold inserts. Photo Credit: Walter

Walter’s Tiger·tec Gold inserts are specially designed for turning operations in all steel applications, including low carbon steels and various alloy steels. The company says a key feature of these inserts is a CVD coating layer that enables process reliability for improved performance and longer tool life.

The layer structure involves a highly textured MT-TiCN (titanium carbonitride) layer which is said to reduce flank face wear and increase toughness due to its multilayered elastic structure. A highly textured aluminum oxide (Al2O3) layer increases the product’s resistance to crater wear, while the gold-colored top layer helps improve wear detection, the company says.

The final multistage posttreatment of these inserts is designed to ensure a rake face with reduced friction for easy chip evacuation and a high level of substrate toughness for resistance to chipping and notching.

With this technology, Walter is introducing three new CVD grades. The WPP10G has the highest wear resistance for continuous cuts primarily in steels (ISO P10) and secondarily in cast irons (ISO K20). The WPP20G is the universal grade capable of handling a range of applications, including continuous cuts to moderately interrupted cuts in steels (ISO P20) and with secondary applications in cast irons (ISO K30). The WPP30G is the toughest grades for steels (ISO P30) and secondary applications in cast irons (ISO K20), respectively. The WPP30G is also well suited for heavy interruptions, castings with scale, older unstable machine setups or any other applications that require a tough grade.

The primary application of these inserts is steels with various tensile strengths that can be machined, where the inserts can significantly help reduce the cost per component.

Walter is offering Tiger·tec Gold indexable insert grades with its signature geometries starting with finishing (FP5), medium machining (MP3, MP5, MU5) and all the way to roughing (RP7, HU5) as well as some other niche geometries for troubleshooting purposes.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Increased Competition Calls for Smarter Solutions

Engineered for efficiency, SW Machines offers customers a full suite of horizontal machining centers and the automation needed for high-volume, high-precision manufacturing.

-

Precision-Driven Performance

Superion solid carbide tools for Swiss applications.