WFL Millturn Technologies, Inc. - USA

48152 West Road

Wixom, MI 48393 US

wfl-usa.com

248-347-9390 bbag@wfl-usa.com

AS SEEN IN PRODUCTION MACHINING

Do you have a new product or news release that should be included here for WFL Millturn Technologies, Inc. - USA? We'd love to include it! Send your content to our editorial team.

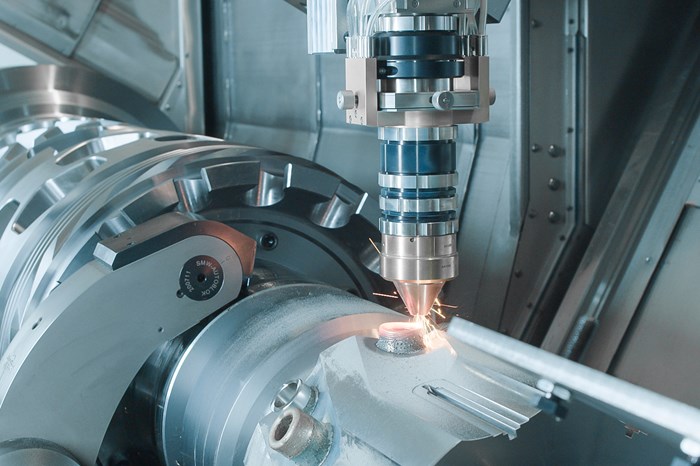

Metal Additive Manufacturing: Multitasking’s Latest Trend

Derek Korn Production Machining magazineWhy are an increasing number of machine tool builders adding additive manufacturing to their equipment’s already versatile machining capabilities? Because additive and subtractive are complementary.

Product categories offered by WFL Millturn Technologies, Inc. - USA:

-

Additive Manufacturing Machines

-

Directed Energy Deposition

-

-

Drilling & Tapping

-

Deep Hole Drilling Machines (Gun Drilling)

-

-

Machining Centers

-

Horizontal, Five-Axis -

Universal

-

-

Turning Machines & Lathes

-

CNC Turn/Mill Machines

-

Trade Names offered by WFL Millturn Technologies, Inc. - USA

- MILLTURN

- Millturn Technologies

Is this Your Listing?

Connect with us to keep your company's information up to date.