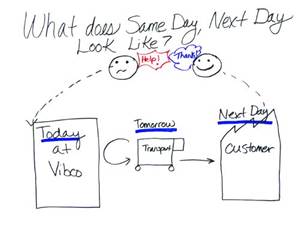

How VIBCO Achieved Lean

VIBCO Vibrators, founded in 1962, manufactures and markets a comprehensive range of industrial and construction vibrators.

#lean

5 Buyer Decisions That Increase Costs

These five factors can unnecessarily add costs or delays to a precision machined part: small order quantities, material selection, special diameter holes, close tolerances, unnecessarily fine surface finish.

#lean

Running Remotely

Everybody talks about unattended machining operations and many have implemented it in varying degrees. Since day one, this Dayton, Ohio shop has never operated any other way.

#lean

The Skinny on Lean Manufacturing

Lean manufacturing—the on-going effort to remove waste from a manufacturing process—has become not only a practice in the metalworking industry, but a culture as well.

#lean

A Problem-Solving Approach: One Size Does Not Fit All

Each day, organizations face challenges to become lean within their shops. Often, the focus of these lean activities is not extended to our management practices. Problem-solving methodology is one such management practice where simplicity is sometimes ignored.

#lean

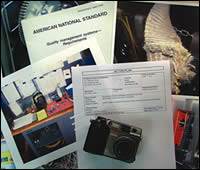

Supporting Lean Manufacturing With Digital Photographic Internal Audits

Visual management has been and will continue to be a key driver in the manufacturing world. Lean principles are predicated on visual activities. 5S — the building block of all lean activities — is based on the motto, "A place for everything and everything in its place." Cellular manufacturing focuses on isolating machinery and tools within an area of the plant in order to increase efficiency. Alarms, flashing lights and other poka-yoke techniques are visual assurances of compliance in work cells.

#lean