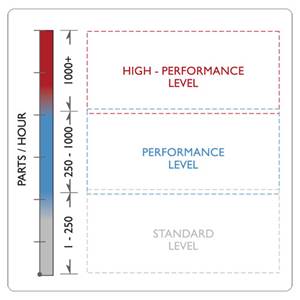

Turning Center Categorization

With the number of turning centers on the market, matching a machine with the right capabilities for a shop's needs can affect price and performance. Thsi article looks at three levels of turning center capabilities and how each plays out various application specifications.

When To Combine Milling And Turning

Turn/Mill technology enables users to complete a workpiece in a single handling. This article looks at some of the criteria that make application of this multi-tasking productive.

#basics

Mill/Turn Centers Spur Shop's Growth With Increased Uptime

After adding a 12,000-square-foot addition onto an existing 32,000-square-foot facility, the management of Nolte Precise Manufacturing (Cincinnati, Ohio) is in the mindset to expand its business and improve its processes, allowing it to grow not only in square footage, but in machining capability as well.

Software Meets Shop's Multitasking Machine Programming Needs

Structure Medical is not new to the medical supply industry; it is a spin-off of a company called Inovo, which is a manufacturer of oxygen regulators used in hospitals, nursing homes and the like. Inovo’s principals had been looking for growth opportunities.

U.K. Shop Is Turned On To Lights-Out Machining

Fisadco Engineering, a Hull, United Kingdom precision machining firm, had some reservations about unmanned machining, but it has become a staunch advocate since it installed a Tornado 220M lights-out turning package from Colchester CNC (Kalamazoo, Michigan) in 2004.

Pipe Fittings Produced In A Single Operation

As with many manufacturers today, streamlining production to stay competitive in the global market has become increasingly important at this company. Thatýs why it sought out a machine to produce a double-ended pipe fitting in a single operation as opposed to having to do the back-tapping in an entire second operation.

One Lean, Mean, Metalcutting Machine

Increasingly, builders are responding to customer demands for part-processing flexibility and reduced part handling by designing machine tools capable of performing numerous operations within a single platform.

Complex Angular Dental Implants...on Multi-Axis Automatic

Just like a car or a machine, the human body benefits from the technological progress of small parts turning equipment. Precision and stringent requirements for safety and stability are essential in the medical industry. In fact, the demands made on surgical screws (bone screws, maxillary-facial screws, implants and so on) and bio-implants can be much greater for the human body than for many industrial and commercial product applications.

Slashing Secondary Ops With New Swiss CNCs

This company employs 55 people. As labor costs have continued to grow, ownership has begun to realize that the only way to maintain profit margins is to become more efficient. Analyzing the operation, they've honed in on eliminating, or it least drastically reducing, secondary operations.

Programming Multitasking Machines?

Applying the right tools and technique to CNC part programming will let shops get the most out of their multitasking equipment.

.jpg;maxWidth=300;quality=70)