Shamrock Precision Production Engineer Edgar Tovar cites better job cost tracking, more accurate quoting and improved machine scheduling as a few advantages of the company’s new ERP system.

When I traveled to Dallas, Texas, in 2019 to present Modern Machine Shop Top Shops benchmarking data at a National Tooling and Machining Association (NTMA) event, I set up a side visit to see Shamrock Precision. Corbin Embrey, who became company CEO earlier that year, had participated in the Top Shops survey nearly every year it was offered, so I wanted to see the operation first-hand because I’d be in his neck of the woods.

During that visit, Embrey explained that the manufacturer — which now focuses on aerospace, medical and oil and gas industries — was in the initial stages of implementing its first true enterprise resource planning (ERP) software from Global Shop Solutions.

Featured Content

Until then, the company had been using a system designed for product distributors. That’s because it was founded in 1981 by Embrey’s parents, Gary and Emy, as Shamrock Bolt and Screw, a distributor of fasteners to medical and energy customers. The company continued to use that system after it transitioned to machining parts in-house in the 1990s. But that system required a number of not-so-efficient workarounds to make it functional in a manufacturing environment, and the process and operational data it tracked was not as precise as it could have been.

At the time of my visit, there really was no story for me to tell because Shamrock Precision was so early in its ERP implementation. So, I stashed this story lead away with my many others with the idea I’d follow up a few years later.

It was a bit of serendipity that I ran into Embrey and one of the company’s young manufacturing engineers at last year’s Precision Machining Technology Show (PMTS) held in Cleveland, Ohio. When I asked if Shamrock Precision was now at the point where I could visit again and write the story about the shop’s ERP implementation, Embrey’s answer was a resounding “yes.”

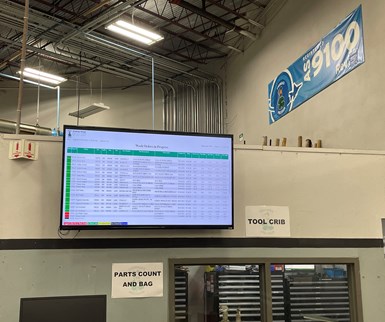

The company is adding large-screen monitors throughout its facility showing, via the ERP system, the status of jobs, which employees are assigned to jobs and so on. With a quick scan, anyone can see how well the shop is currently performing.

That said, I also learned that the company has recently implemented other technology to grow the business and streamline its processes as it strived to diversify its customer base, which Embrey admits had been focused on oil and gas. The key, he says, has been taking a crawl, walk, run approach to making such process improvements.

So, while the application stories I write for Production Machining often focus on one new technology or piece equipment from which a shop is benefiting, I decided to take a different approach with this article. Consider this to be a “snapshot in time” in terms of where Shamrock Precision currently is with its recently adopted manufacturing approaches, equipment and technology.

Crawl, Walk Then Run with ERP

Once Shamrock Precision realized it needed a true manufacturing ERP system, it considered a few providers. In fact, it was the company’s operation in Malaysia (established in 2008 to support the oil field service industry in Southeast Asia) that suggested Global Shop Solutions, in part, because this ERP provider seemed fully capable of supporting the company’s needs in that region while offering ERP standardization between it and the Dallas headquarters.

Embery says he also appreciated that Global Shop Solutions was a family-owned company that started in the oil and gas industry just like Shamrock Precision; was located nearby in Houston and offered free training; and had similarly branched out to other industries such as aerospace (a market his company was looking to further penetrate). After a demonstration with the team in Dallas, the company selected Global Shop Solutions in April 2019, although it didn’t go live with the system until March 2020.

We succeed taking a crawl, walk, run approach when adopting new technology.

That’s because, before going live, Shamrock Precision ran systems in parallel in two different ways. The Malaysia operation was the first to implement the new ERP system, the idea being that lessons learned there would flatten the learning curve for the Dallas facility.

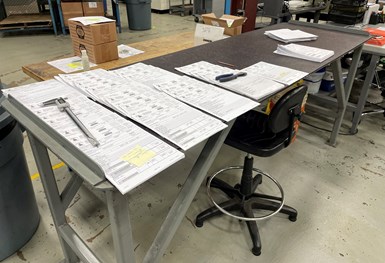

Shamrock Precision still produces paper travelers for those on the shop floor as that still works well for machine setup personnel and operators as a means to easily view all the details of a given job.

What also helped was running the new ERP system concurrently for a time with Shamrock Precisions’ existing system. Embrey says, while it was a bit of a burden to enter the same data into two different systems at the same time for a little while, it helped ensure no details would fall through the cracks once the new ERP system went live and enabled employees to experiment with the various features and modules it offered.

What Shamrock Precision has found is that this new system serves as a much better means to track activities, time and costs while providing improved communication and visibility for both the front office and the shop floor. Here, Production Engineer Edgar Tovar offers a brief overview of some of the system’s benefits.

- Better job cost tracking. ERP enables a more effective way to tie employee time, material and tooling to a given job, while providing one platform for accessing all of that information.

- More accurate quoting. Similarly, by comparing actual job cost to the estimated cost, adjustments can be made when quoting the same job again or one that’s very similar. It might be that a setup took longer (or shorter) than expected, so the time for that can be changed for the next quote or the production schedule modified to account for it.

- Improved machine scheduling. The ERP system’s Advanced Planning and Scheduling module enables planners to view what jobs are scheduled for every machine to determine if the shop is ahead or behind on a given job based on estimates calculated during router creation. This helps determine if it makes sense to move a job to a different machine. In addition, knowing the status of a job enables Shamrock Precision to verify expected delivery dates to customers when asked. Basic color changes in the system warn planners if a job is trending toward a late delivery.

- Increased work status visibility. Shamrock Precision is adding large-screen monitors throughout its 36,000-square-foot, climate-controlled facility. This shows the status of jobs, which employees are assigned to a job, what tasks they have clocked into and so on. It also offers a way to see, in a quick scan, how the shop is performing overall.

Tovar says he also appreciates the ability to customize his dashboard to best suit his needs. For example, a column for material cost for each job was recently added so there is no need for him to dive deep into a work order to find that information. Plus, it’s possible to switch to a test company mode to experiment with functions with which he currently isn’t experienced without the worry of affecting the actual system. This is important especially as the shop is still early on in its use of ERP. There are many modules that a manufacturing company might find valuable at some point or modules that it might only being using a portion of. Maintaining a concurrently running test company helps personnel learn more about the various ERP functions and experiment with them without disrupting the actual system.

He also points out that, while ERP can minimize or possibly eliminate the need for or use of paper, Shamrock Precision still finds paper travelers to be valuable. Jobs need to be scheduled in ERP and digitally available to him and others such as account managers and the quality team. But, the company still produces paper travelers for those on the shop floor as that type of system still works well for machine setup personnel and operators as a means to easily view all details of a given job.

The proprietary software for the tool vending system the company developed enables it to set minimum stock levels and provide information such as tool cost, current inventory level and cabinet location. Users scan a bar code each time a tool is removed for tracking purposes.

Additional Improvements

During my recent visit, I also learned more about other technology Shamrock Precision has added and processes it was refining. Here are a few examples.

Tool inventory management. A few years ago, Shamrock Precision began developing its own tool storage and management system using proprietary software it developed. The software enables it to set minimum stock levels and provide information such as tool cost, current inventory level and cabinet location. Users scan a bar code each time a tool is removed for tracking purposes. Once the inventory level for a tool reaches its minimum level, the tool description text is highlighted in red. Managers can sort the tools identifying those that have reached their minimum level and purchase additional items if there is an immediate need for them. Embrey says, in time, he envisions this being tied to the ERP system so tool inventory data will be accessible there.

CAM software specifically for Swiss-types. Another example of technology Shamrock Precision very recently added is the SolidCAM programming software it purchased to program its eight Marubeni Citizen-Cincom Swiss-type lathes. On-machine programming was becoming a bottleneck (as on new jobs on those sliding-headstock machines) when the same person creating programs at the machine also performed and dialed-in setups and ran the job. Offline programming enables that person to focus on setups and then running the machine while the part program is created offline. The software integrates directly into SolidWorks and offers full associativity, meaning design changes initiate automatic tool path updates.

A cobot will soon free quality personnel from manually loading parts onto this optical inspection system so they can perform higher value duties.

Automated optical inspection. Part measurement can become a bottleneck, especially for high-volume production shops. Devices such as noncontact optical systems from Oasis Inspection Systems automatically measure multiple profile dimensions on small parts simultaneously and in real time with all measurements done in less than a second. Shamrock Precision has one of these units in its quality lab. However, the process still requires an employee to load and unload parts on the unit. That’s why the company is integrating a cobot from Universal Robots for automatic part loading currently for one high-volume job, which will enable deft inspectors to perform higher value duties.

A conveyor moves parts under a camera system, which detects part orientation and communicates this to the cobot so it grips each part properly. The cobot then picks and delivers a part to the inspection system in the proper orientation. Two images are taken for each part, and the robot will rotate each part after the first image for the second to be taken. Embrey says the company will eventually add a newly available rotary table Oasis now offers for these devices to automatically rotate the part for those two shots rather than tasking the robot to do that.

Vises like this are used for some jobs that run on the company’s five-axis HMC. The jaws grip onto indentations stamped into the bottom of a workpiece to provide high clamping force while offering ample clearance for cutting tools around the blank.

Horizontal machining. Once Shamrock Precision started getting more into aerospace work, it began considering horizontal machining centers (HMCs) with pallet changers as an alternative to vertical machining centers (VMCs). The company recently added its first HMC, a five-axis Makino a500Z providing 360-degree B-axis rotation and 180 degrees of C-axis tilt by way of a “slant-style” trunnion design. Makino says this enables workpiece positioning ranging from the pallet top being horizontal to the spindle centerline to parallel to the spindle centerline. This model also offers active, closed-loop temperature control on all axes, which is said to ensure accurate dimensional control and extend machine component life. Embrey also points to the production benefits of the machine’s fast tool changes. (Tool-to-tool change time is 0.9 second.)

In addition, Shamrock Precision secures some workpieces for this machine using Lang Technovation Makro-Grip vises on zero-point, quick-change interfaces. The Makro-Grip vises grip part blanks in an unconventional way. A stamping machine is used to squeeze either side of a blank along its bottom and uses “teeth” that create multiple indentations in the blank. The blank then installs in the vise that has jaws with mating indentation profiles. This form-fit connection is said to provide high holding force even though the vise grips on only a small portion of the blank. It also provides the cutter/toolholder with ample clearance around five sides of the part during machining to minimize the risk of collision.

At some point, a robotic cell might be created around this B-axis turn-mill, including a shopfloor CMM to enable part measurement right at the machine.

What’s Next?

During my visit, Embrey suggested a number of other ideas the company is considering to expand capacity and improve process efficiencies. It is very likely to add an additional Swiss-type to handle some of the challenging aerospace materials the manufacturer is encountering. And, he can envision installing a second HMC next to its first and integrating both into an automated, flexible manufacturing system for pallet storage and retrieval as the company continues to win more aerospace work.

In addition, Embrey says the lessons learned with the cobot in the quality department will help it more quickly integrate robots to tend machine tools. For one aerospace customer, the company will likely create a cell around its Okuma Multus B-axis turn-mill that includes a shopfloor CMM for statistical process control.

Embrey says this last idea is a prime example of Shamrock Precision’s crawl, walk, run mentality. The cobot automation for inspection gets the company up the robotic learning curve so it is able to more briskly run when it comes time to place robots in front of production equipment.

RELATED CONTENT

-

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

-

Bar Feeder Basics

Some primary factors are often overlooked when considering how to justify the implementation of a bar feeder for turning operations.

-

10 Smart Steps to Take Toward Recovery

With many manufacturers facing challenges in light of the novel coronavirus pandemic, these 10 steps can help position manufacturers to find success.