Editorial, News, and Products

Manufacturing Automation Beyond Robots at PMTS

A variety of automated machining and manufacturing processes — including, but not limited to, robotics — that can enable shops to become more efficient were on display at the recent Precision Machining Technology Show.

PMTS 2021 Product Preview: Automation and Measurement

Learn about some of the new automation and measurement solutions for precision machining that will be on display at PMTS 2021.

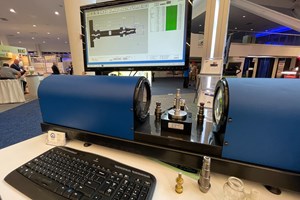

Oasis CoreX2 System Measures Multiple Dimensions

PMTS 2019: The CoreX2 inspection system is said to be the largest field of view Oasis Inspection System that measures multiple dimensions on a part.

Value-Added Inspection

Few in a production turning environment would argue the fact that, generally speaking, the need for better accuracies has steadily risen right along side increased workpiece complexity. But verifying these accuracies is still often a tough pill to swallow, considering the non-value-added nature of inspection.

Fast Inspection Adds Dollars to the Bottom Line

Putting out good products and being profitable are what it’s all about in the machining business.

Small Parts Have Big Impact

Advanced micromachining capabilities have had a monumental effect on the way parts are produced. But as parts continue to get smaller, complexities increase, as do corresponding tolerance requirements.

Faster Measurement Of Complex Parts

As workpieces become more and more complex, with numerous critical dimensions that must be correct because they often relate to other features of the part, many of the tried-and-true measurement tools can slow down the production process.