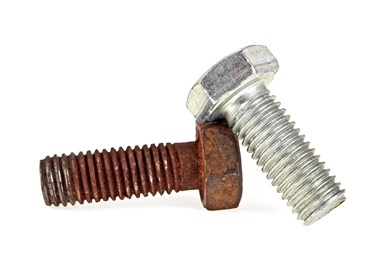

No matter where you are, there are certain times of the year when humidity increases and if you are working with untreated metal, you probably have had an issue with corrosion or rust. Understanding what happens to that metal part next is always the deciding factor of how you deal with it. How clean does it have to be? Can it be too clean? Will it be painted or treated? How will it ship? Navigating the options can be a little intimidating and finding a trusted source is where being a member of the MCA is a big benefit.

We have posted a new paper in our Technical Resources section titled Corrosion Prevention Procedures for Metal Parts to help turn those bad words into good words like long-term protection and prevention. As our membership grows, so does the shared technical information of our collective group, meaning you can get exclusive access these resources any day, any time.

Featured Content

If you know someone that has technical experience and expertise in cleaning, or if you know someone that would benefit from getting access to our technical resources, we would love for them to join and become another good word: a member.

Make sure to check our website when you can as we are adding new and useful info all the time. If you are not finding the answers you need – feel free to contact any of the board of directors or send an email to info@manufacturingcleaning.org and we will connect you with someone to help.

Keep your metal parts, and your words, clean.

President, MCA