Digital Twin Makes CNC Programming Easier

A digital twin helps to reduce or eliminate any surprises that may occur during the machining process.

Edited by Lori Beckman

Using Esprit CAM software, Pacific Swiss and Manufacturing Inc. moved from three-day to week-long programming sessions to one day.

Photo Credit: DP Technology

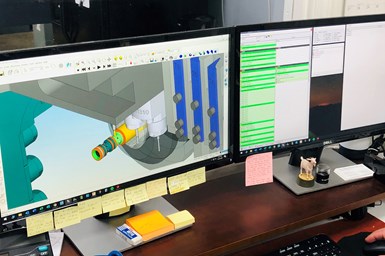

A digital twin duplicates a CNC machine and its environment, including its setup on the shop floor, within the CAM software, providing accurate toolpath simulation, according to DP Technology. A digital twin helps to reduce or eliminate any surprises that may occur during the machining process. It includes barstock representation, the workholding fixture components for multiple operations and solid models of toolholders that can be downloaded from tooling manufacturers’ websites.

The Machining Cloud App and tooling data/measurement systems are the latest programs that link cutting tools directly with CNC programming. The Machining Cloud App, for example, includes complete tooling catalogs from dozens of tooling manufacturers to enable the CNC programmer to download the exact tooling assembly, thus extending the digital twin to the tools and holders being used in each machine. As a bonus, users can define their CNC machines in the app, which can help the system recommend the appropriate tooling as well as feed and speed data directly from the tooling manufacturer.

The digital twin also includes an edit-free postprocessor. The NC code produced using the postprocessor can go directly from the CAM software to the finished part with a minimal, or in many cases, no dry run. Also, no manual editing of code at the machine is necessary.

Stay tuned for an application story that illustrates the importance of the digital twin.