Continuous improvement has always been critical to Schmid Tool and Engineering (STE) in Villa Park, Illinois. That’s why its management knew when it was time to hire an outside professional to help the team implement some lean manufacturing principles. Doing so enabled the team to pinpoint processes that could be improved in its business that supplies parts to the firearms industry. After the company implemented two Hydromat Inc. rotary transfer machines, it experienced an increase in its on-time deliveries rate, a reduction in its scrap rate and a reduction in its backlog.

When the family-owned company hired Erik Poulsen (who had 21 years of experience in precision machining) as the director of operations, he voiced concerns about the way the hammers and triggers were being machined after he built a value stream map. The map’s resulting information was used to identify where to maximize value and minimize waste throughout the business.

Featured Content

At that time, the parts were manufactured on dedicated custom rotary index machines and secondary operations. Poulsen was bothered by many inefficiencies this process caused, including multiple part fixturing, high scrap rates, part family scheduling issues, machine reliability, changeover complexity, quality standards, downtime, maintenance and more.

He took these issues to STE’s owners, Eric Schmid and Heidi Schmid Schaefer. They gave Poulsen and his team of engineers permission to explore new manufacturing options for the hammer and trigger cells.

A Family Legacy

In 1943, Gustav K. Schmid, an immigrant from Germany, opened a small tool and die shop in Chicago, Illinois. Over time, STE developed into a full-service CNC contract machine shop specializing in machining small castings. Today the 3rd generation owners of the shop, Schmid and Schaefer, are the grandchildren of Gustav Schmid.

Michael Mechnig, manufacturing engineer technician, adjusts the EPIC HF program on one of STE’s indexing chuck machines. Photo Credit: Hydromat Inc.

Following almost 80 years of machining parts for military, firearms, vending machines, exercise equipment, recreational vehicles and medical industries, the majority of its business today is dedicated to the firearm industry.

Choosing the Right Solution

Experienced in the precision machining industry, Poulsen knew the solution to the company’s inefficiencies would be to integrate a rotary transfer machine. After receiving numerous quotes from several rotary transfer manufacturers, the STE team opted to invest in two Hydromat Epic HF HS-16 indexing chuck machines. “When it came down to choosing between rotary transfer machines, we moved forward with Hydromat because of its location, level of quality and specifically its level of service,” Poulsen says.

Hydromat worked closely with the Schmids and the rest of the STE team to provide a turnkey system fit to their needs.

Applying the Technology on the Shop Floor

By December 2021, the new rotary transfer machines were delivered to the company, and accommodations were made to implement the machines on the shop floor. In comparison to its existing knowledge of CNC machines, the Hydromat machines’ level of complexity meant more moving parts than the company was familiar with. But STE simplified the approach to learning the new technology and viewed the machine as what it is – 16 spindles or 16 individual machines in one.

“We had a slight learning curve to overcome, but nothing significant we couldn’t handle with the help of Hydromat support,” Poulsen explains. “We have now trained our machine operator and two night lead associates on how to run the machine and complete changeovers.”

The engineering team has since come to learn the machine and how to modify programs. It has changed the tool path to clip-off burs and driven down the cycle times.

Flexibility Increase and Waste Reduction

Prior to implementing the rotary transfer machines, STE did not have the option to complete changeovers due to the reliability of the manufacturing cell. Their previous custom rotary index machines were dedicated machines, which led to many scheduling issues. This caused problems when trying to meet the production requirements of each part in the hammer and trigger part families.

But now with the new machines, the hammer and trigger cells are hitting their production goals. In fact, the company has increased on-time delivery by 85%, reduced scrap rate by 98% and cut its previous backlog by 90%.

This diagram displays AR-15 firearm parts manufactured by STE. 70% to 80% of AR-15s in the United States include Schmid products. Photo Credit: Schmid Tool and Engineering

“Before January (2022), we ran 40,000 units between the two Hydromat machines and only scrapped 24 units,” Poulsen says. “The two machines have brought many improvements to the Schmid manufacturing process: minimum downtime, increased quality, repeatability, flexibility, ease of scheduling part families and quick changeovers.”

By producing three variations of hammers on machine one and four variations of triggers on machine two, the company can quickly and efficiently produce these parts.

“Depending on the complexity, our changeovers range from 30 minutes for program changes or approximately one hour for changing out chuck jaws,” says Paul Calzaretta, manufacturing engineering manager.

New Business Opportunities

Now that STE has increased its production and quality, the company wondered how it could take steps to increase brand recognition and brand loyalty by selling products directly to dealers and firearm shops. Hence, Schmid Inside was born.

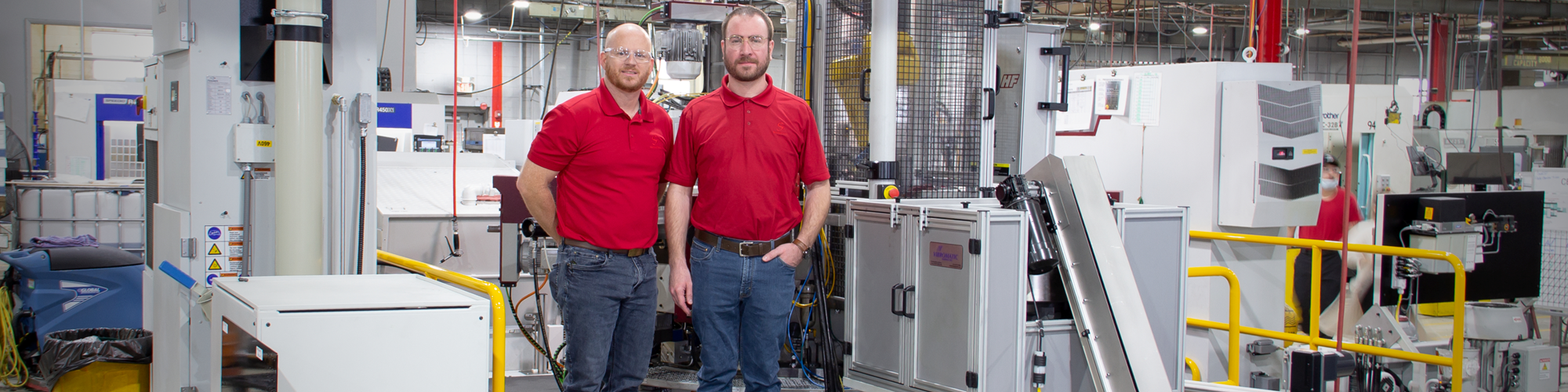

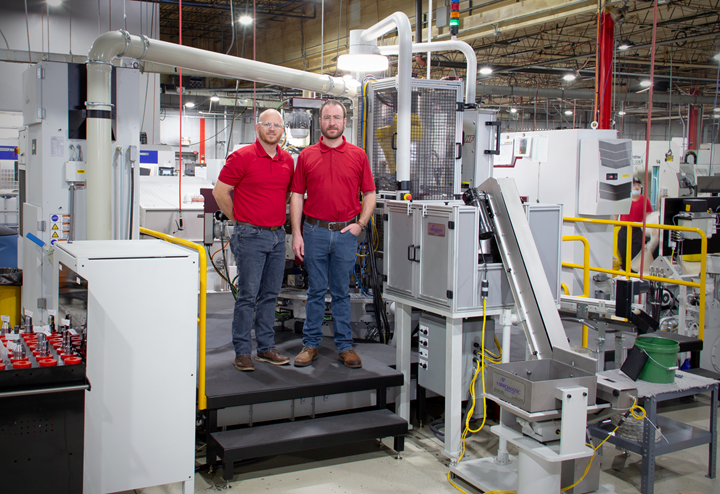

Erik Poulsen, director of operations, and Paul Calzaretta, manufacturing engineering manager, stand on the EPIC HF HS 16 indexing chuck platform. This is STE’s one of two production cells producing a family of parts on Hydromat machines. Photo Credit: Hydromat Inc.

This direct B2B storefront and source for products manufactured by STE includes its Gun Nuts product line and other Schmid Inside branded products available in bulk and retail packaging.

STE also launched the Wee1Tactical JR-15 rifle, which is a .22 caliber long rifle. This smaller rifle was created to develop a line of shooting platforms that will safely introduce small stature shooters to shooting sports, the company says.

The company is currently working on the smaller fixturing required to produce this new rifle’s trigger and hammer parts on its Hydromat machines.

Hydromat Inc. | hydromat.com

Schmid Tool and Engineering Corp. | schmidtool.com

RELATED CONTENT

-

Shop Continually Improves by Adopting Rotary Transfer Machines

American Turned Products’ founder left a legacy of continuous improvement, helping the company grow as it implemented rotary transfer machines and preparing it to take on new work.

-

Rotary Transfer: Turning Up the Volume

This contract manufacturer set its sights on high volume, precision turning and assembly of complex components from Day 1 and continues to succeed in a market many have abandoned using CNC rotary transfer machining.

-

A Different Kind of Machining Center

If one horizontal machining center is good, then three on a single platform should be better, right? That’s the thinking behind the Multicenter concept from Italian builder, Porta Solutions. It blends the volume production capabilities of rotary transfer technology with the flexibility of a machining center in a single platform.