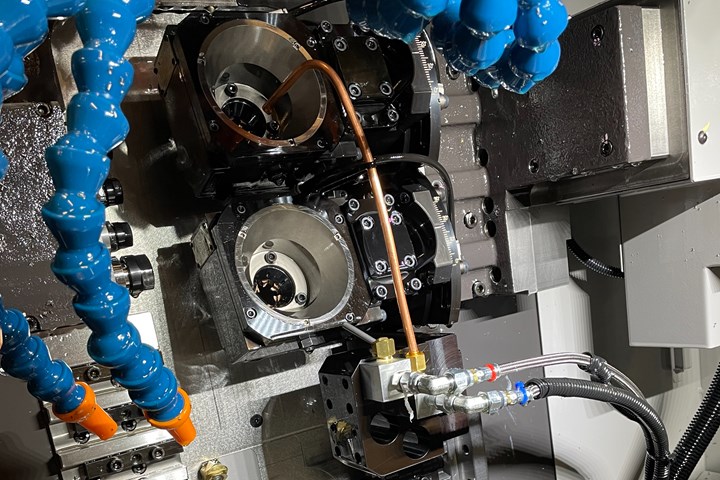

Video Tech Brief: Dual Thread Whirling on a Swiss-Type CNC Lathe

The dual thread whirling units on Tsugami Swiss-type lathes can produce medical bone screws with two different thread leads in one setup, eliminating the need for single-point threading.

In some cases, medical bone screws have two thread leads. Traditionally, these might be machined with two single-point threading operations, or, one thread whirling operation followed by a subsequent single-point operation.

Tsugami/Rem Sales offers an alternate option on its S206-II Swiss-type CNC lathes that can be fitted with two thread whirling attachments. That way, both thread leads can be created in one setup. View the video above to learn more.

RELATED CONTENT

-

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.

-

A New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.