Debunking the Deburring Process

Appears in Print as: 'Solving a Cross-Bore Deburring Issue'

A car manufacturer struggled with a complex and unreliable deburring process for its crank case production line until it was introduced to a tool designed specifically for cross-bore deburring.

#techbrief

A German car manufacturer recently found itself in a cranky mood regarding its crank case production line. Though everything else in the line was humming along, deburring cross bores in the crank cases required a complex and unreliable process that was grinding away its production time, not the leftover burrs.

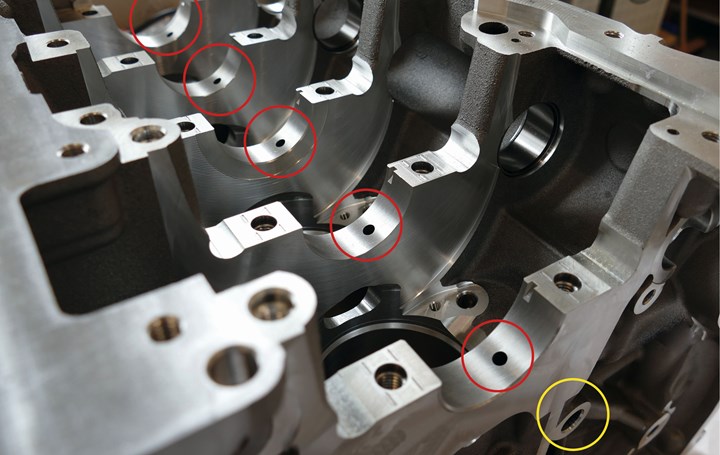

The crank case has five cross-bore oil holes (red) that intersect with the main bore hole (yellow). The unevenness caused by the geometric conditions at the points where the bore holes intersect ruled out the use of conventional deburring tools. (Image courtesy of Heule Precision Tools.)

Many machinists have found themselves in a similar situation — deburring cross holes is a stubborn problem requiring multiple pass-throughs that still don’t get the job done. The car manufacturer used two deep-hole drills and drove through the boreholes 8 to 10 times each. Despite repeated deburring, burrs remained and required visual inspection and reworking. At 1.4 million components per year across five production lines, each extra pass to deburr adds up quickly.

Finding a Solution

The manufacturer’s head of technology went to the AMB trade fair in Stuttgart, Germany, to discuss the problem with Heule, a leading producer of deburring tools. The head of technology knew the supplier from a previous deburring project and knew the company could offer a tailored solution to the cross-hole problem.

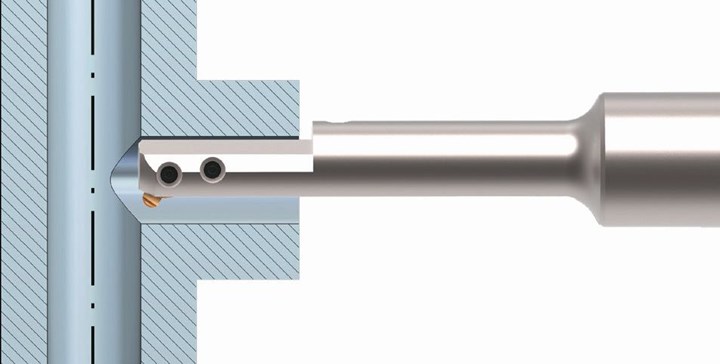

The solution was a deburring tool based on COFA-X, tailored to the specific application like all cross-bore deburring tools. It is suitable for all intersecting bore holes up to 1:1. (Image courtesy of Heule Precision Tools.)

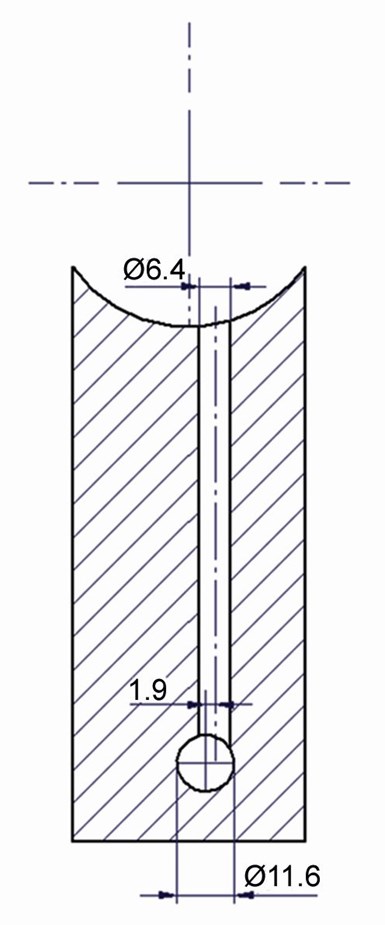

The intersection of the cross bore (6.4-mm diameter) with the main bore hole (11.6-mm diameter) caused a large unevenness with an eccentricity of 1.9 mm. (Image courtesy of Heule Precision Tools.)

Not only was deburring, itself, a complicated process, but the car manufacturer had specific needs that made the process even more nuanced. The intersection of each cross bore (6.4-mm diameter) with the main bore hole (11.6-mm diameter) caused a large unevenness with an eccentricity of 1.9 mm. Conventional deburring solutions and standard products available at the time just weren’t up to the task.

Heule worked with the car manufacturer to create a product that would suit its needs. The first solution proposed had a large control housing that the manufacturer didn’t have the space for in its facility. Heule went back to the drawing board and came back to the manufacturer with the COFA-X, a revision of its COFA tool designed especially for cross-bore deburring.

After months of testing and communications back and forth, the car manufacturer commissioned Heule to repeat in its production plant the successes it had in the development laboratory. By the third run, the automated deburring process was corrected and optimized to perform the task without error.

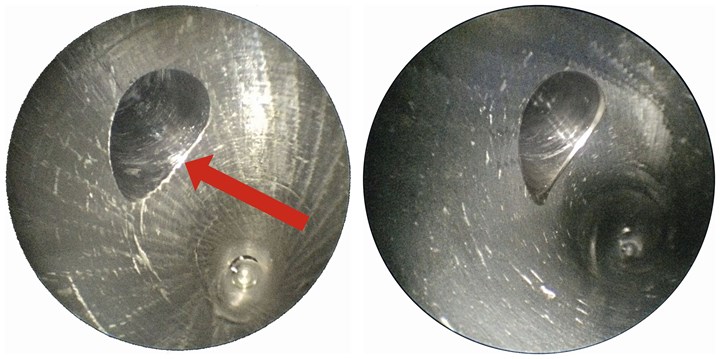

The quality officer visually inspected the chamber using an endoscope and confirmed the result: “No burrs.” The quality of the deburred surface was even better than before. The manufacturer was ready to get the line back up and running for mass production.

The arrow indicates the burrs on the unprocessed borehole (left). The new tool removes burrs in a mechanically defined, more reliable way, shown on the processed borehole on the right. (Image courtesy of Heule Precision Tools.)

Cross-bore deburring, a process that once took 8 to 10 passes and then even more fine tuning, can now be done in one pass with one tool and one operator. Heule’s initial testing showed that each COFA-X could process about 7,000 boreholes, enabling the manufacturer to deburr the crank cases more reliably and with less tool downtime than before. The results had the car manufacturer feeling a lot less cranky.

Heule Precision Tooling | 513-860-9900 | heuletool.com

RELATED CONTENT

-

Getting Ready for Lights-Out Manufacturing

Lights-out manufacturing has the potential to save money while increasing capacity, but shops need the right equipment and to address potential challenges before implementing it.

-

Profilometer Choices

Learn the difference between skidded and skidless profilometers that can be used to measure the surface roughness of machined parts.

-

Medical Screw Solution Includes More than Cutting Tools

With companies producing so many medical screws, every second saved counts. A turnkey program can help manufacturers machine these parts as efficiently as possible.

.png;maxWidth=970;quality=90)