The Story Behind a Machining Background Photo

The photo I added to my LinkedIn page shows the application of nifty CNC technology enabling a turn-mill to machine a complex medical device complete. It certainly seemed appropriate.

It’s the innovative application of CNC machining technology like this that I hope to discover and present to you in my new role with the magazine.

I had to make a number of changes when I joined the Production Machining editorial team. Picking a new background photo for my LinkedIn page was not high on my list of things to do, but it was on my list, nonetheless.

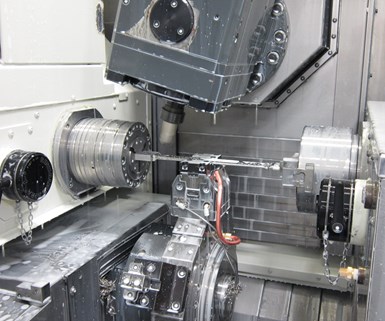

Over the years, I have visited a number of shops with Swiss-types and turn-mills, so I knew I had taken multiple photos that might be well-suited. When I revisited this story about Alpha Manufacturing and Design’s use of a Nakamura-Tome Super NTMX bar-fed turn-mill with B-axis milling spindle, lower tool turret, and main and subspindles of equal horsepower, I found the photo shown above. (These machines are distributed by Methods Machine Tools.)

The photo captured a few process elements that enable the efficient, complete machining of a stainless steel chisel with a knife feature used for surgical procedures. For instance, Alpha uses rectangular stock instead of round stock to minimize the amount of material to be removed. (That said, quick-change collet chucks enable fast changeovers to round bar stock for other parts.) The shop also added work tailstocks, supports and pneumatic clamping devices to some of stations on the machine’s lower turret stations to enable more effective milling operations with the B-axis head. As shown above, a pneumatic clamping device positioned under the chisel handle helps counteract tool pressure to minimize chatter. Stepped jaws enable it to clamp stock of different sizes. This device also provides support while machining the knife feature that has a wall thickness of only 0.1 inch. The knife feature can’t be seen in this shot because it and a portion of the handle near that end of the chisel has been swallowed (and is now supported) by the machine’s subspindle.

Alpha also found that by positioning the B-axis head 15 degrees from vertical, a ballnose end mill could finish a groove on the chisel part twice as fast as when it was oriented normal to the part. It also leaves behind a better surface finish.

It’s the innovative application of technology like this I hope to discover and present to you in my new role with the magazine.

Previously, this chisel, which requires machining on all six sides, ran across four machines and took one hour and 45 minutes to complete. The turn-mill with interesting tooling and workholding strategies now produces the part complete in 35 minutes.

It’s the innovative application of technology like this I hope to discover and present to you in my new role with the magazine. And it’s why this made the ideal photo for my LinkedIn page. In fact, that page has proven effective in spurring discussion and interaction between page visitors. Here are two recent examples:

-This post asks visitors to offer advice to a manager of a screw machine shop who is considering implementing lean manufacturing.

-This post asks for visitors’ reactions to the cancellation of IMTS 2020 as well as any neat memories they have about past shows.

Feel free to visit those posts and share your thoughts. Also, email me if you have adopted some advanced process that you feel would make for a nice article in our magazine. Or, if there are topics you’d like us to cover, please let me know.

RELATED CONTENT

-

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.

-

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

-

Dry Swiss Machining in Medical

Continuing to build its reputation for creative solutions, this multi-faceted medical device component manufacturer took its Swiss machining operations to a new level to meet a customer’s market demands.