Alphacam 2017 R2 Features Key Automation Capabilities

Vero Software’s Alphacam 2017 R2 software automates key CAD/CAM operations and includes the Automation Manager with enhancements to simplify workflow, including multi-drill control, styles functionality, and further support for additional CAD file formats.

#Industry40

Tool Data Management Software Supports Industry 4.0.

TDM Systems’ TDM 2017 and TDM 2017 Global Line combined software platform for tool data management systems replaces version 4.8. and emphasizes supporting Industry 4.0 by providing data transfer and can also be used in parallel to existing applications.

#Industry40

Mastercam and Kennametal Partner to Provide Tool Automation

CNC Software Inc., developers of Mastercam, has partnered with Kennametal Inc. to provide customers with the ability to import tool assemblies from NOVO directly into Mastercam 2018, allowing Mastercam customers to save time searching and building 3D tool assemblies.

#Industry40

Magnetic Spindle Encoders Have Functionally Safe Axes

Heidenhain Corp.’s ERM 2200 magnetic modular angle encoders have functional safety in mind as the growing EU standard trend is to require functionally safe axes on machines.

#Industry40

Moving Toward a Smart Factory with Manufacturing Analytics

MachineMetrics Inc. has identified a gap in machine monitoring, as manually tracking data can be inefficient to track and can be inaccurate and reactive, but real-time data allows companies to make fast, proactive decisions to bring efficiency to their processes.

#Industry40

Shop Automation in the Front Office

This article speaks to the success one shop had in automating its ERP system using a new software package.

#Industry40

Automation Helps Improve Employee Productivity

Stark Industrial LLC’s first stand-alone robot works within a new turning machine cell that is currently dedicated to the simple machining operation of processing a cast aerospace part that is proprietary and is the further step the shop needed to gain process control.

#workforcedevelopment #Industry40

Tour Showcases Plant-Wide Connectivity

Mazak’s North American headquarters, located in Florence, Kentucky, has been manufacturing multitasking, five-axis, turning and milling machines since 1974 and was recently reimagined as a Mazak iSMART Factory concept.

#Industry40

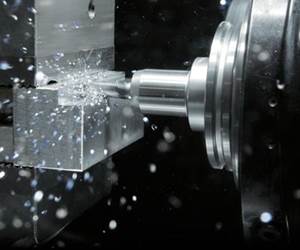

Preparing Precision Turning for Industry 4.0

Ready or not, Industry 4.0 is moving forward, and it’s critical for manufacturers to be ready for it. Many machine tool builders and accessory builders are equipping their products with Industry 4.0 compatibility in anticipation of its implementation by customer shops.

#Industry40

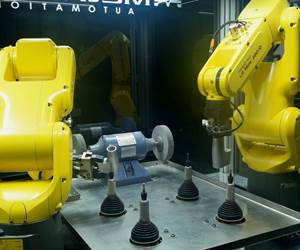

Robot Monitoring Provides Safe, Flexible Automation

Working hand-in-hand with customers to further develop robot safety technologies, ABB recently introduced SafeMove2, which provides added capabilities to allow for the creation of more efficient and flexible production scenarios and to integrate safety fieldbus connectivity into the company’s IRC5 robot controller family.

#Industry40

Methods Machine Tools Launches Automation Center in Charlotte

To meet the demand for automation and robotics in manufacturing, Methods Machine Tools is expanding its automation capabilities with a 10,000-square-foot Automation and Integration Center in Charlotte, North Carolina.

#Industry40

Developing a Platform for Data-Driven Manufacturing

With the eventual goal of adding machine condition monitoring, this company began by installing an ERP system as a foundation to build upon, flattening the learning curve with each step toward achieving increased process oversight.

#Industry40

New Venture Poised for Industry 4.0

The synergies made possible by the Walter-Comara collaboration enable Walter to digitize and connect its tools with improved precision and sophistication, allowing optimization of real-time data.

#Industry40

Reducing Production Times with Robotic Automation

A complete overhaul of its processes using lean principles helped this shop improve production by almost 90 percent.

#Industry40

Increase Throughput with Off-the-Shelf Automation

This automated parts accumulator is designed to complement any bar-fed CNC lathe, providing hours of profitable, unattended operation by safely collecting and organizing finished parts.

#Industry40

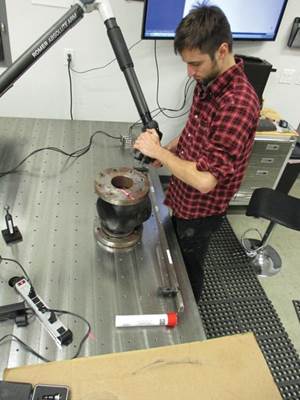

Metrology Looks at Industry 4.0

Every shop makes parts, but making them correctly is the role of measurement and inspection.

#Industry40

Flexible Automation on a VMC

Robot loading and unloading of the workholding that is used in the machining center facilitates the ability to change jobs during an unattended run.

#Industry40

The Next Industrial Revolution Nears

Having an understanding of the term Industrial Internet of Things is important because from what I’m hearing and reading, this emerging technology gives rise to what is predicted to be the next Industrial Revolution.

#Industry40

The Digital Driven Machine Shop of the Future

How CAM software, the cloud and the Internet of Things are converging to change the way our industry is doing business.

#Industry40

Moving Automation In

This traditional Ohio-based screw machine shop worked with a system integrator and used its in-house expertise to create a sophisticated production cell to go along with its other automation forays.

#Industry40