Hexagon Edgecam 2022 Software Supports 6-Axis Machining

The software also supports 3+2 machining and complex 5-axis simultaneous milling in all configurations.

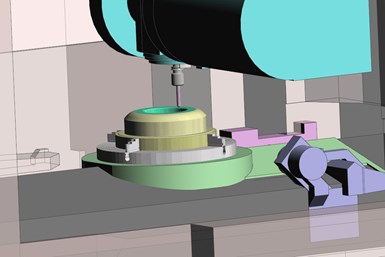

Edgecam 2022 simulates turn-mill with X axis on the spindle. Image Credit: Hexagon

Hexagon’s Edgecam 2022 software features added support for 6-axis milling and turning machines. Horizontal machine tools with two programable axis in the head can been synchronized with a rotary table. This enables users to program the cutter head into positions previously out of reach in one setup, which in the past required a series of sequences.

The software also supports 3+2 machining and complex 5-axis simultaneous milling in all configurations.. A Select Rotary Axes command enables the user to activate the preferable axis to machine. Regardless if users are machining wireframe or solid models, the software is said to produce toolpaths 2-3 times faster than previous versions.

The updated software is also designed to reduce calculation time by enhancing Edgecam’s multithreading processing capability, which gives a productivity boost when working with the roughing cycle.

Users who formerly possessed the standard 5-axis milling license (EN050-S) will now find that the advanced 5-axis milling cycle (EN050-A) has been automatically added to the configuration. This affects both 4-axis and 5-axis cycles. As the name implies, the advanced cycle is said to offer more functionality and gives users improved toolpath control.

Also integrated with Edegcam is a component called NCSIMUL Essential, which is said to provide full simulation of 3-axis milling parts. NCSIMUL is Hexagon’s high-end CNC simulation software for G-code verification. Users can dynamically interact with a toolpath and pinpoint exactly which line of code is being simulated. Multiple cross-section planes can be created to interrogate the resultant workpiece. Once simulated, the workpiece can be measured in a variety of different styles, including arc, thickness, hole center distance and more. Critical dimensions and stock analysis can be generated through the comparison tool.

Related Content

-

Get with the Program(ming): 10 Articles to Help You Transform Your Data

Collecting data but not sure how to use it? You’re not alone. See how smart shops are turning raw machine data into real results—better decisions, smoother operations, and measurable ROI.

-

5 Tips for Multichannel Programming

Programming for multitasking machines can be complex. Knowing several key points for making the process less challenging can save a programmer time as well as lessen confusion and the risk of error.

-

Who Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.