Editorial, News, and Products

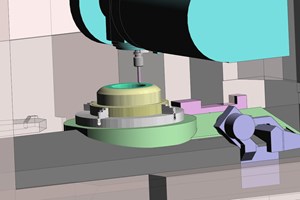

CAM Software Simplifies Complex Parts

Intuitive interfaces and automated steps are making CAM programming easier for new users, even as parts and the machines that produce them increase in complexity.

Radan CAD/CAM Sheet-Metal Software Combines Customer Orders

Radan CAD/CAM sheet-metal software is a provider of applications for the design and manufacture of sheet metal components and products.

Alphacam Nesting Engine Provides Faster Calculation Times

Vero’s Alphacam 2018 R2 nesting engine has enhancements to the software’s dimensioning system that provide greater clarity when printing and presenting information.

Software Offers Robot Programming

Simulation and singularity resolution tools in Vero Software’s WorkNC 2018 R1 can take full advantage of the benefits robots bring to the manufacturing process.

Direct Modeling System Fills Gap Between CAD and CAM

Vero Software’s Designer is a stand-alone, optional application for a CAM portfolio, enabling users to create designs or modify existing geometry from third-party CAD systems.

WorkXplore High-Speed CAD Viewer Converts Files in Batches

Vero Software’s WorkXplore is a high-speed CAD viewer and analyzer that can import and analyze files in batches and at high speed and has a batch-converter function that allows batches of CAD files to be converted to the WorkXplore format.

Vero Hires Darin Weatherbee as Applications Engineer

Vero Software has hired Darin Weatherbee, who brings to the Vero team experience with the company’s Surfcam solution, as applications engineer to expand its support network.

Vero Software Offers Edgecam and Surfcam Training

Vero Software now offers software training opportunities for Edgecam and Surfcam users in Wisconsin and surrounding states at the Waukesha, Wisconsin, facility of Vero parent company Hexagon Manufacturing Intelligence.

Chris Carter to Represent Edgecam and Surfcam in Southwest

Vero Software has hired Chris Carter, a veteran of the U.S. Air Force and graduate of ITT-Technical Institute who has held sales positions in the industrial automation industry, as the account manager to represent Edgecam and Surfcam in the Southwestern United States.

Alphacam 2017 R2 Features Key Automation Capabilities

Vero Software’s Alphacam 2017 R2 software automates key CAD/CAM operations and includes the Automation Manager with enhancements to simplify workflow, including multi-drill control, styles functionality, and further support for additional CAD file formats.

CAD Viewer Helps with Job Estimating

Vero Software has recently released a high speed 3D viewer that directly displays and evaluates 3D CAD files without the need for the original CAD application.

Handling Machining Complexity with CAM

With the increase in demand for closer tolerances on difficult-to-machine parts, shops look to improve efficiency through simplified processes.

Software Creates Perfect Tool Paths for Five-Axis Machining

A week’s programming with Edgecam CNC software provides a U.K. manufacturer of orthopaedic instruments with 12 weeks of machining time for its highly complex products.

Free CAM Software Test Drive

At no cost and zero risk, manufacturers can now take Edgecam Workflow from Vero Software for a free test drive before deciding if the company’s CAM system can improve their business processes.

It’s Good to be the Queen

Vero Software, a British based provider of CAD/CAM/CAE solutions for the manufacturing industry, has been awarded the Queen's Award for Enterprise in International Trade for 2014.

Lunch & Learn Events Offer Software ‘Test Drive’

Edgecam will partner with select resellers this year on a series of “Lunch & Learn” events, where attendees will have the opportunity for a live test drive of Edgecam 2014 R1 Workflow, to see firsthand how Workflow’s intuitive interface, model intelligence and knowledge-based machining enables them to rapidly complete the steps of CNC machine programming for prismatic parts.

In-Kind Grant Gives Students Access to Popular Technology

TST Tooling Software Technology and Vero Software have made an in-kind grant of $750,000 worth of Edgecam software to Lawrence Technological University.

Accuracy Helps Swiss Watches Keep Perfect Time

Production engineering solutions required by many Swiss watchmakers are already installed in their CNC machines when they buy them.

Edgecam Celebrates 30 Years

Yes, I thought the photo was of some sort of cake to celebrate Edgecam’s 30th anniversary. I was wrong. But that does not take away from the fact that the software manufacturer was founded in 1983.

More Machining, Less Time

The latest features of Edgecam CNC software (2012 R1) were recently highlighted at the Innovation for Productivity event, held at Mazak's European technology center in the UK.

Turn-Mill Classics

Here are trailers for some of the classic articles on turn-mill multitasking. This is a broad showing of turn-mill technology in the form of machines, processes, programming and applications.

In-House Productivity Preserves CAM Investment

This shop launched a major upgrade of many of its manufacturing operations 3 years ago. The facility received ten new CNC machine tools, three multi-spindle turning centers and five mill/turn machines. To achieve the expected return on investment for the biggest machine, new CAD and CAM systems were installed.

Winning New Jobs With Online Bidding

The digital revolution is hitting the business of the multiple-spindle automatic machining--in two distinct forms, no less. Twenty-five years after the first wave of digitization in manufacturing (numerical control) its linear descendant, computer numerical control or CNC, is changing the way screw machine shops do business.