Schwanog's Insertable Tools Ground Individually

By: Tarah Rauch - Gardner Business Media

PMTS 2019: With its PWP and PWP-D insertable form drill system, Schwanog is said to address the problem of high setup times as the insert holder stays in the machine during insert changeover.

#PMTS

EDM and the Precision Parts Industry

By: Chris Felix - Production Machining

Although EDM often is not at the forefront of concern for precision machined parts shops, it can play a big role in the production of tooling that these shops use.

Using Grinding Versus EDM to Finish Form Tools

By: Barbara Schulz - Gardner Business Media

Finishing carbide inserts using EDM or grinding.

#basics

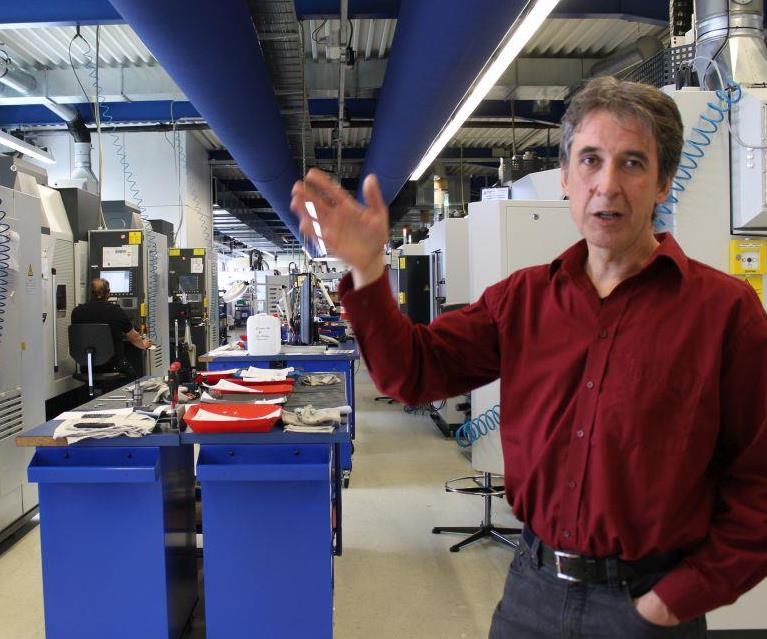

Production Machining in Germany

By: Chris Koepfer - Production Machining

This week I’m reporting from the Schwabian region of Germany, where metalworking has deep roots and good technology.

Save Time with Polygon Turning

By: Chris Felix - Production Machining

Polygon turning provides the capability to manufacture both flat surfaces and radii.

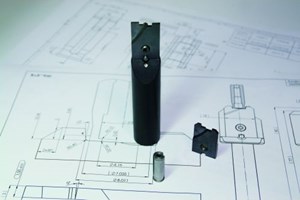

Insertable Form Drill System Enables Company to Bore Large Diameters

By: Lori Beckman - Products Finishing

Nass Magnet (Hanover, Germany) invested in a new machining center with a rotary transfer machine with eight stations for double-sided machining.

Insertable Form Drill System Provides Quality Surface Finish

By: Lori Beckman - Products Finishing

To be able to manufacture the components of electro-pneumatic valves in production batches of millions, Nass Magnet (Hanover, Germany) invested in a new machining center with a rotary transfer machine with eight stations for double-sided machining, which came with drills from another supplier.

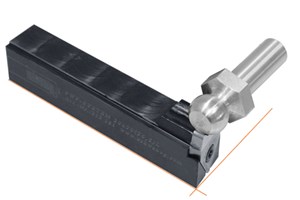

The Skiving Solution

By: Chris Felix - Production Machining

Shaving operations are often the solution for a shop that needs to produce round diameters and other tough contours with tolerances within ± 0.0005 inch.

Insertable Form Drill System for Maximum Efficiency

By: Chris Felix - Production Machining

In many applications, the switch from solid carbide drills to insertable form drills has shown to provide unit cost reductions of as much as 40 percent. As the demand for highly complex parts continues to rise, production improvements such as these become even more significant.

Creating the Indexable Insert

In the shop, we are often told how to use a cutting tool, but not necessary the mechanics behind the tool itself or how the tool is manufactured. A few articles Production Machining has published in the past discuss this topic.

#basics

.png;maxWidth=970;quality=90)