Editorial, News, and Products

RW Screw: Where Automating Processes is a Common Thread

This Northern Ohio contract machine shop increasingly integrates automation, in all its forms, as it adapts to the reality of a continually diminishing talent pool.

Geared Up for Quality

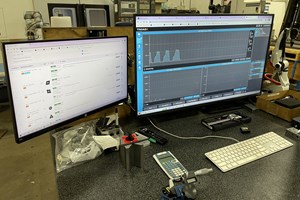

This shop realized that its part inspection station worked fine for smaller lot sizes, but it was inadequate for the shop’s high volumes. But after investing in an image dimension system that measures multiple part features simultaneously, the company can use the measurement unit on other jobs as well.

Shop Gears Up for Quality

When one shop employee learned that her employer, Forest City Gear, was purchasing an IM Series automated inspection machine from Keyence, she looked forward to the time it would save on incoming inspection of gear blanks from outside suppliers.

Machines Simplify Inspection of Multiple Parts

When multi-tool creator Leatherman Tool Group Inc. (Portland, Oregon) was looking for new technology to improve its measurement capabilities, company management was hoping to find a measurement system that offered easy programming and operation, efficiency, and the ability to hold tight tolerances.

Measuring System Speeds Up and Simplifies Inspections

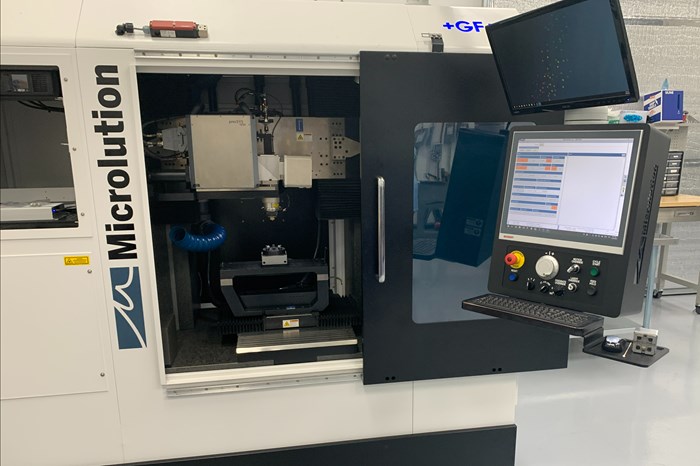

Fralsen, Timex’s entity in Besançon, France, realizes that in order to run an efficient process to the end, the time it takes to do these things without error is especially important, even during part inspection.

Probing for Quality

Committed employee owners are the foundation of this company’s achievements in high precision manufacturing.