Addressing Micro-Boring Challenges

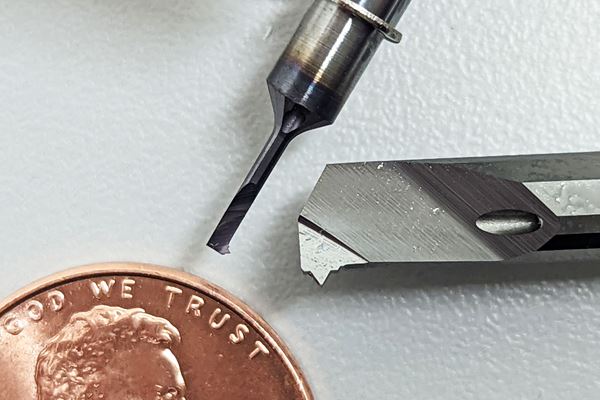

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

Derek Korn

Editor-in-Chief, Production Machining magazine

Micro-Drilling: 9 Questions to Answer Before Beginning

Applications for micromachining continue to grow. Successful machining with small tools calls for a different set of process skills on the shop floor.

Where Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

Micromachining Turns Images of the Queen into Tiny Portraits

Engineers at the University of Sheffield Advanced Manufacturing Research Center (AMRC) used a turn/mill center to reproduce a series of tiny portraits of Queen Elizabeth II, down to only 1.4 mm wide, onto brass.

Laser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Walter Micro Drill Has Internal, External Coolant Capabilities

Walter USA’s Supreme DB133 solid carbide micro drill delivers high precision and productivity.

Speed Matters in Microtooling Applications

A variety of tooling spindle options brings micromachining work within reach for shops looking to expand their capabilities.