Haimer Shrink-Fit Machine Features Integrated Cooling

Power Clamp Air i4.0 Eco provides smooth and clean cooling of all kinds of toolholders or collets by air, without dirt and water residue.

Precision Machining Technology Review September 2023

Production Machining’s September 2023 technology showcase includes some of the latest technology from Lyndex-Nikken Inc., Kurt Workholding, Master Fluid Solutions, Rego-Fix Tool Corporation and Jorgensen Conveyor & Filtration Solutions.

#metalworkingfluids

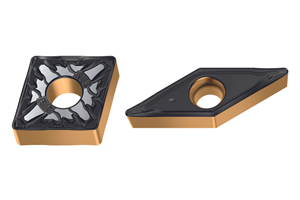

Walter Turning Grades Reduce Machining Times

The WKP01G and WPP05G grades are ideal for continuous cutting and occasional interrupted cuts in high-tensile materials.

Dillon Claw Jaws Enable Aggressive Turning

The jaws are designed to securely grip workpieces and minimize jaw clamping force losses.

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Kurt Workholding Vises Provide All-Directional Alignment

The DXH Hydraulic vise lineup features the proprietary Kurt AngLock spherical segment to reduce jaw lift and improve performance.

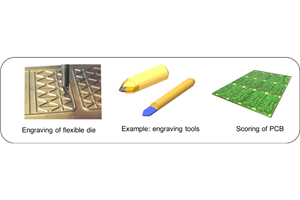

Lach Diamond Inc. Engraving Tools Provide Wear Resistance

PCD- or CBN-tipped engraving tools enable competitive machining strategies for processing magnetic flexible dies as well as cutting rotors made of high-quality, challenging materials.

Rego-Fix Toolholding System Reduces Coolant Consumption

MQL PG collets are designed for machines using one-channel, internal through-spindle MQL systems.

Video Tech Brief: Bar Feeder Technology Optimized for Swiss-Types

This bar feeder design is said to offer high guidance quality with minimum vibration and noise development for sliding-headstock machines.

Lyndex-Nikken Toolholders Offer Stable, Versatile Machining

Polygonal shank toolholders provide a rigid connection between the tool and machine — ideal for all processes both in turning and milling.