You Can't Cut it if you Can't Hold It

Read an article we published that speaks to the changes that many shops are experiencing when dealing with the trend toward low volume/high mix jobs and the increasing need for precision workholding.

Precision Workholding Keeps Quality High for Gun Manufacturer

Keeping up with the latest and best processes is important for any shop, even one that produces a product that has been manufactured since the Industrial Revolution.

Precision Cartridge Mandrel for Internal Clamping

A new mandrel provides consistent workpiece ID clamping of very small diameters for grinding, turning, milling, drilling and measuring.

New Clamping System Shortens Setup Times

The more quickly a setup can be completed, the sooner a machine tool can begin cutting chips. A new clamping system from GF Machining Solutions provides just that.

The Collet is the Answer

A small workholding change helped this shop deliver the required part finish by resolving vibration and runout issues.

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.

Bar Puller Features Self-Adjustment

The EZ-Puller, from Accudyne Corp., addresses a series of bar puller concerns with its own approach to pulling barstock.

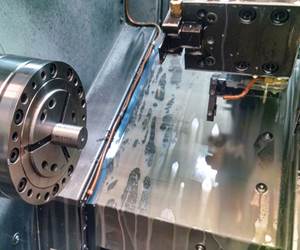

Bar Feeder Automates Part Production

Designed to boost productivity through streamlined operation, Haas Automation's latest bar feeder model is built for use with Haas ST-10 through ST-35 and DS series CNC turning centers.

Load and Unload Pre-Processed Workpieces

The best application for this loader is in shops that process saw-cut, semi-finished, extrusions, forgings or castings and near-net shape blanks in CNC turning centers and multitasking machines.

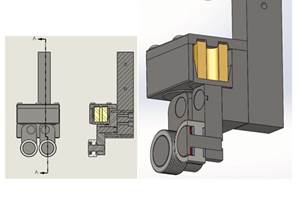

Subspindle Workholding Options

The advent of subspindle turning operations has impacted throughput for many shops. Understanding workholding options available for backworking can help a shop make better decisions when specifying how to hold parts for op. 20.

#basics