Generating More Efficient Milling Tool Paths for Multitasking Machines

This toolpath generator can reduce cycle time and extend tool life while helping achieve better surface finishes for milling operations on multi-axis Swiss-types and turn-mills.

#techbrief

Edited by Lori Beckman

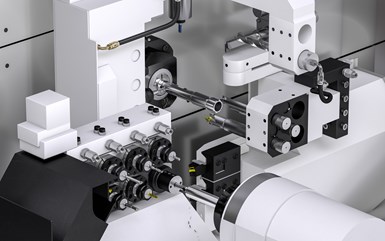

To enable shops to become more efficient with milling operations on multitasking machines, SolidCAM has developed its iMachining toolpath generator within the company’s CAD/CAM software. Photo Credits: SolidCAM

Because they offer the potential to machine parts complete is one reason shops are drawn to turn-mills and Swiss-type lathes. And, as part geometry continues to increase in complexity, there are cases in which just as much — if not more — milling is performed on those machines than turning.

To enable shops to become more efficient with milling operations on multitasking machines, SolidCAM has developed its iMachining toolpath generator within the company’s CAD/CAM software. The toolpath generator is said to be able to reduce machining time by as much as 70% and increase tool life.

Featured Content

It does this by employing high-efficiency milling to reduce cycle times by using solid end mills, small stepovers, fast feed rates and deep axial depths of cut. The company says the key to achieving the high material removal rates is generating optimized, morphed spiral tool paths with variable cutting angles and feed rates at every point of the tool path that creates a constant spindle load.

This strategy avoids shocks that occur when material engagement changes abruptly such as when a tool enters the corner of a pocket. Without this capability, feed rates must be managed for the worst-case cutter load scenarios, making cycle times longer. Moreover, maintaining a constant spindle load substantially reduces vibrations, thus yielding increases in tool life as well as better surface finishes.

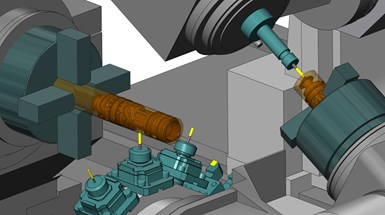

The ability to visualize simultaneous operations on a single screen enables building a better-balanced program with faster cycle times.

The ability to visualize simultaneous operations on a single screen enables building a better-balanced program with faster cycle times.

Because multitasking machines are significant investments and might not have a large tool capacity, shops need the ability to compress machining time, yet extend tool life as much as possible. According to SolidCAM, that’s what iMachining does.

One could conclude that because this software is more aggressive with the cutting speeds and feeds that a tool would wear out quickly. But the company says that is not the case. Carbide is an extremely hard material — it can stand up to compressive forces beyond most other materials, and it is also highly resistant to abrasives. These factors make it well-suited for cutting tools used for cutting steel, superalloys and most other metals.

However, carbide is also very brittle and therefore does not stand up well to tensile (bending) force. The iMachining is designed to ensure that the carbide substrate at the sharp edge of the solid carbide tool flute never sees tensile force — it only sees compressive force. Therefore, the sharp edge resists microchipping, even at elevated performance levels, resulting in improvements to tool life, the company says.

Another way the software increases tool life is with its ability to make use of the full cutting depth of the tool while never overstressing the tool. It is designed to spread the forces over a large area, maximizing tool life by using the full length of the flute instead of only the bottom 10% as might be the case for traditional milling practices.

The toolpath generator can be especially useful on Swiss-type machines when milling with small-diameter tools.

The toolpath generator features several automatic abilities that increase ease-of-use for the machine operator. Its Technology Wizard, for example, is designed to eliminate practically all the guesswork involved with setting the machining parameters. The user chooses the level of aggressiveness by using a slider to adjust on a scale of 1 to 8, which alters cutting data to achieve higher material removal while staying within the constraints of the machine and cutting tool. Then, the Technology Wizard automatically calculates optimal feeds and speeds.

Other automatic characteristics include iMachining 2D, which handles the roughing, semifinishing and finishing of prismatic parts. The iMachining 3D replaces multiple standard roughing and semifinishing operations of complex 3D shapes in one step.

The toolpath generator can be especially useful on Swiss-type machines when milling with small-diameter tools. For example, a 0.015-diameter end mill at the full depth of cut can be routinely used. Even smaller tools can be accommodated based on the way that iMachining controls the engagement angle (radial depth of cut).

SolidCAM also provides other functionality to streamline and simplify programming of multifunction machines, such as:

- Integrated simulation. This is said to offer a fast, safe and effective way to generate validated code. Because it simulates synchronized channels throughout the process, it enables programmers to balance simultaneous operations more easily.

- Virtual Machine ID. With this function, users can tailor the software for a specific machine by defining electromechanical elements such as maximum spindle horsepower, speed and feed rates.

- Machine Control Operation. For turning centers with a subspindle, this function synchronizes part transfers and pick offs automatically.

- Toolpost management. Tool Table enables managing of the toolposts with predefined tool assemblies. Special functionality for Swiss-types enables direct entering of tool setup values to the software.

- Multichannel Synchronization. Mill-Turn and Swiss Multichannel Synchronization specializes in factoring in the machine kinematic limitations and the controller limitations when synchronizing parallel multiple tasks.

SolidCAM | solidcam.com/en-us

RELATED CONTENT

-

Swiss Shop Chooses CAM Over Hand Programming

This shop’s manual (by hand) CNC programming was slowing it down until it discovered a CAM software for Swiss-type lathes.

-

CAD/CAM’s Role in How Machine Shop Benefits from its First Swiss-Type

This manufacturer of high-end RC cars leverages the capabilities of its CAD/CAM software to get the most out of its first Swiss-type lathe even when job batch sizes are relatively low.

-

Why Using Pirated Software is Riskier Than Ever

Machine shops and manufacturers that use pirated software risk losing much more – both directly and indirectly.