The precision machining industry faces a relentless challenge to constantly find new ways of increasing productivity, while ensuring the continued production of high quality components. Highly efficient tooling and machining methods involve raising feed rates, boosting cutting speeds and increasing the depth of cuts – all while maintaining the all-important quality.

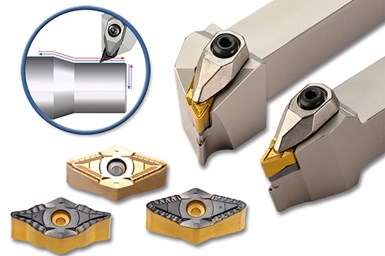

Cutting tool manufacturers are rising to this challenge. This month, our Technology Showcase is highlighting some of the product information that PM received from supplier companies. For April, we focused on cutting tools, including standard coated-carbide ISO-P steel insert grades for common steel turning operations; drilling units customized for particular operations; IG6 and SG3 coatings for cartridge tooling systems; and more as described below.

Featured Content

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s March Technology Review.

Click on each link below to read the full product post:

RELATED CONTENT

-

Skiving Long, Slender Parts with Tight Tolerances

Here's a look at one of the oldest and most efficient methods of screw machine production for parts that are long and slender, with close-diameter tolerances and finishes, or parts that require truly spherical radii.

-

Understanding CNC Collet Chucks

Workholding for turning is usually fairly basic: The selection comes down to chucks or collets. This article looks at when to consider the collet chuck and what kind might be best for a given application.

-

Advantages of Cellular Manufacturing

Manufacturing cells are used to minimize product movement as well as materials, equipment and labor during the manufacturing process. By reducing cycle times and material handling, these cells help shops more easily meet customer demands regarding cost, quality and leadtimes.