Precision machining paired with automation and robotics can offer unprecedented levels of speed, accuracy and quality control for manufacturing processes. Automation can also help companies advance to more lights-out production as well develop a continuous-improvement mindset that can enable increased efficiencies in numerous areas.

Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For February, we focused on automation and robots, including a machine tending robotic cell featuring portability, easy setup and programming; air rest buttons using pneumatic position control to properly detect workpiece loading in a fixture; an automatic door opening solution for robotic machine tending that can be fitted to any CNC machine in under an hour; and more as described below.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s February Technology Review.

Click on each link below to read the full product post:

Photo Credit: Mitsubishi Electric Automation

The LoadMate Plus Machine Tending Robotic Cell from Absolute Machine Tools’ partner Mitsubishi Electric Automation streamlines part loading, unloading and palletizing in low-to-high volume applications. It features portability, easy setup and programming, high performance, and a safety-first design that make it appropriate for both job shops and larger scale production environments, the company says.

Carr Lane Manufacturing Part Loading Solution

Photo Credit: Carr Lane Manufacturing

Carr Lane Manufacturing’s Air Rest Buttons (ARB) use pneumatic position control to properly detect workpiece loading in a fixture, the company says. Consisting of a threaded body installed in a fixture, these units hold a precision floating plunger. Once proper placement of a workpiece on the ARB assembly occurs, the plunger fully retracts into the body, which is designed to seal off airflow and increase the system’s overall pressure. The pressure value can be read using an analog or digital pressure system.

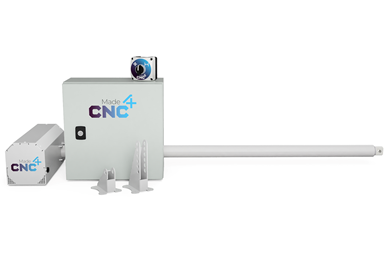

Made4CNC’s Safedoor SD100 is said to be the world’s first completely automatic door opening solution for robotic machine tending, and can be fitted to any CNC machine in under an hour. The company says the Safedoor SD100 removes barriers to the automation of component feeding at machine shops with its ability to open CNC doors that are up to 1 meter wide and weigh 400 kg, at a speed of 500 mm/sec.

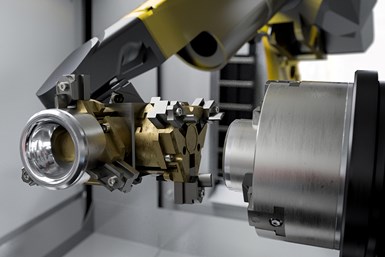

FANUC America’s Robomachines line includes the LR-10iA/10 robot, which is designed for machine tending. Weighing 46 kg, the LR-10iA/10 robot mounts to the floor, upside down or on an angle. The company says it is also simple to mount the robot to an AGV or other mobile platform to accommodate a variety of repetitive tasks or automate machines that are standing idle.

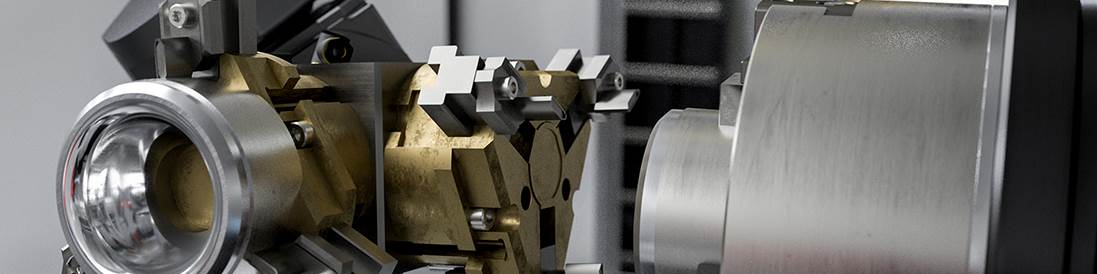

Photo Credit: United Grinding

United Grinding’s Studer RoboLoad system offers manufacturers simple, seamless part-loading automation for CNC radius internal grinding machines such as the Studer S121, S131 and S141. The company says, until now, loader integration could be intrinsically difficult on these types of machines because of the height of their workheads and associated geometric restrictions.

Comau’s Racer-5 Cobot is a collaborative robot designed to function fast and efficiently in restricted spaces and in a variety of applications. The cobot is a 6-axis articulated robot that can work at industrial speeds up to 6 meters per sec. With a 5-kg payload and 809-mm reach, it is said to ensure optimal industrial efficiency while offering safe, barrier-free operations.

RELATED CONTENT

-

Here's a broad look at different ways to approach workholding, from bar feeders to collet chucks to robotics.

-

After years of relying on an extensive machining cell for part production, this marine equipment manufacturer has now reduced part handling and improved quality through use of single-setup lathes and automated loading and unloading.

-

Selecting the right bar feeder can be one of the most important decisions a shop can make. Bar feed systems help improve productivity, throughput and quality, but in order to achieve the most benefit from them it is essential that a bar feed system be matched to the particular needs of the turning operation.