Single-Cell Automation Simplifies Shop's Growing Production

By: Lori Beckman - Products Finishing

Ask Michael Olano, president of Dynomach Inc., how to be a profitable high-volume production shop. His answer: self-contained, single-cell automation, or more specifically, twin-spindle machines outfitted with bar feeders and automatic parts catchers.

#Industry40 #basics

Celebrating Technology and Education

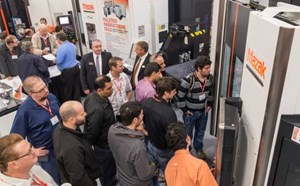

By: Chris Felix - Production Machining

From October 8th to the 16th, Mazak Corporation’s North American Headquarters held its Discover 2013 technology-driven manufacturing solutions event.

#workforcedevelopment

Open Doors Can Open Minds

By: Chris Koepfer - Production Machining

Increasingly, the message to manufacturers looking to keep manufacturing strong for the future is that it’s up to us as an industry to get the message out. There is no help coming from anybody but us.

Mazak Event Offers Technical Seminars and Metalworking Demos

Companies seeking new technology, advanced manufacturing solutions and valuable industry insight to increase their production efficiency and global competitiveness should consider attening Mazak Corporation’s Discover 2013 event, taking place Oct. 8-16, 2013, in Florence, Ky.

Mazak Event Targets Aerospace, Medical

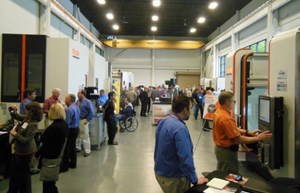

By: Chris Felix - Production Machining

While in the area for EASTEC last month, I attended Mazak Corporation’s “Discover More with Mazak” event at its Northeast Technology Center in Windsor Locks, Conn. The 3-day event highlighted a lineup of the company’s manufacturing systems.

Mazak Honored for Continuous Investment in Manufacturing Campus

In recognition of the expansions of its North American Headquarters campus in Florence, Ky., Mazak Corporation received the Cincinnati USA Partnership for Economic Development’s Growth Award during the Commercial Real Estate Developers Power Breakfast event held on May 2, 2013, in downtown Cincinnati.

Multitasking Benefits a Process in Many Ways

By: Lori Beckman - Products Finishing

Multitask machining is the ability to perform various manufacturing operations unattended, without moving the part to other machines.

Exceeding Expectations with Multitask Machining

By: Lori Beckman - Products Finishing

Implementing a multitasking machine with new CAM software enabled setup and production time reductions for the shop. One part even went from a setup time of 6 hours to 5 minutes.

Shop Gains Process Control with Automation

By: Chris Koepfer - Production Machining

Eliminating variability from the manufacturing flow is a goal for most shops. Automation can allow reallocation of resources to accomplish this.

#Industry40

Stepping Up to Unattended Machining

By: Chris Koepfer - Production Machining

Lights out, unattended machining is a goal for many precision machined parts manufacturers. For many parts using easily machined materials, the process is fairly straightforward. However, this Ohio shop uses a systematic process to maximize unattended machining of more difficult materials.