Keeping Pace with CAM

The latest version of this CAM pacakge features 5-axis simultaneous machining for multi-axis lathes, improved milling functionality and enhanced thread whirling support.

Don't Chase Variability with CAM

A recent study showed that mechanical SuperTuning of a moderately priced CNC machine could dramatically improve volumetric positioning accuracy.

One-Part Solution With Huge Payoff

Machine shops prioritize different challenges daily, but some challenges are more critical than others. Precise Products Corporation (Minneapolis) was faced with a challenge when one of its original customers asked the company to reduce the cost of a family of parts or risk losing the job.

Machining In Paradise

One medical parts job shop is taking its business to the next level in Puerto Rico with the right CAM system.

Macro Programming

In recent years, macro programs have been created to replace the practice of writing a separate program for every part number. The reason: Macro programs react to geometric variations across broad part families and therefore are more efficient compared with NC programs that are dedicated to particular parts.

Software User Interface Updates

The company has revamped the PartMaker user interface, improved capabilities for programming directly on solid models and the ability to automatically generate descriptive and visual setup information. The user interface features easy-to-use, user-configurable toolbars. Existing icons have been recast to make them easier to understand, the company says.

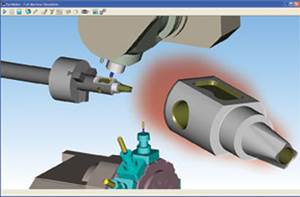

Multitasking with Enhanced Lathe Features

GibbsCAM MTM (multitask machining) now includes lathe features that are said to provide more efficiency through tool control and take advantage of newer high-tech cutting tools that turn harder materials and machine smoother surfaces.

CAM Software Offers Ease of Use

The Esprit 2009 CAM software is designed to save time and money by importing solid models, recognizing features on those models and automatically drawing options from a database of machining practices for the machining of those specific features and for a range of machine types. The KnowledgeBase user interface has been centralized to make it easier to manage all of the data in the database, the company says. The single, consistent user interface allows users to access all the data from one central location, such as the processes, materials and cutting tools, and context-sensitive commands are available with a right-click of the mouse.

CAM For Multitasking Operations

While still running a few different CAM systems in the shop, this manufacturer of aerospace and oil and gas industry components has implemented what it sees as the ideal package for programming its multitasking work.