Low Frequency Vibration Increases Job Shop’s Productivity

With the ability to machine difficult materials more efficiently while improving surface finish, this job shop is reaping the benefits of its Swiss-type lathes that incorporate low frequency vibration.

#workforcedevelopment

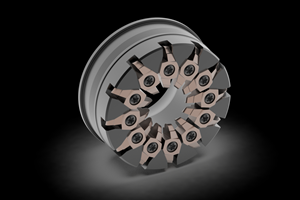

Advancements in Thread Whirling Tooling Technology

Many understand the advantages of thread whirling on a CNC Swiss-type. However, new tooling technology for this thread-machining process can further improve cycle times and reduce cost per part.

Expand Machinery’s Genturn-52 CS Simplifies Setup, Reduces Costs

Sliding headstock machine has no guide bushing, thus simplifying setup while reducing job expenses and setup time.

7-Axis Swiss Lathe Features Built-in Motor Spindle

Machine is built for rigidity, accuracy, reliability and ease of use.

NexTurn SA-20B Swiss Lathe Offers 7-Axes

Machine is built for rigidity, accuracy, reliability and ease of use.

Tsugami B-Axis Swiss-Type Machines Complex Shapes

Swiss CNC Lathe cuts precise angles and sculpted contours, reducing number of required tools and decreasing changeover time.

Carving Out a Niche in CNC Plastics Machining

This Vermont shop focuses solely on machining plastics — some filled with abrasive glass — for a range of industries. That makes it stand apart from others, but means it also faces challenges that metal machining shops often don’t encounter.

Precision Machining Technology Moving Shops Forward

New equipment and software continue to be developed to support the needs of production machine shops like yours. Here’s a sample of technology now on the market that can help you grow your operation and become more efficient.

MCC Lathes Improve Productivity, Operating Convenience

MCC’s M532 VIII and L12X have added capabilities to improve productivity.

Swiss Shop Turns Precision into Profit

The quality demands for micro-machined parts are swiftly increasing. Shops must be ready and willing to adjust their machining strategies to fit the need.