Automated Multitasking Machine Drops Parts Complete

This automated multitasking machine with an integrated robot eliminates the need to run parts across multiple machines, saving floor space, setup time and manpower.

#techbrief

The Value of Dual Thread Whirling Units for Bone Screws

Dual thread whirling units on a Swiss-type enable it to produce medical bone screws with two different thread leads in one setup, eliminating the need for time-consuming, single-point threading.

#techbrief

Future-Proofing a Parts Cleaning Process with Modified Alcohols

Modified alcohols can be reliable replacements for the solvents currently under scrutiny by the EPA. These non-halogenated solvents have good drying qualities, are very stable and have low surface tension.

#techbrief

Medical Screw Solution Includes More than Cutting Tools

With companies producing so many medical screws, every second saved counts. A turnkey program can help manufacturers machine these parts as efficiently as possible.

#techbrief

Automation Brings Reliability to Laser Marking Bone Screws

To overcome human error in laser marking, consider a reliable, high-throughput automated system designed to run 24/7.

#techbrief #Industry40

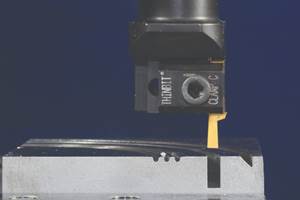

A New Face Grooving Technique for Mills

Here is an alternative to standard end milling — an operation performed on a CNC milling machine to produce circular grooves in the part face. This new single-point trepanning tooling strategy can produce both symmetrical and asymmetrical face grooves, too, and perform fly cutting.

#techbrief

Cutter Considerations for Turning Titanium

Effective titanium turning requires the proper selection of cutting tools and machining processes to mitigate the effects of the material’s unique chemical and physical properties.

#techbrief

Ceramic Inserts Can Boost Turning Productivity

When applied correctly, ceramic inserts can dramatically increase cutting speeds, providing shorter cycle times and cost savings compared to carbide for turning operations.

#techbrief

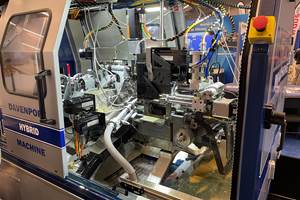

What’s Still Cam-Driven and Why?

Combining select cam-driven functions with CNC technology for this multi-spindle platform is said to help reduce machine cost while retaining high machining speed, precision and production.

#techbrief

Fast Change Tooling System Increases Spindle Uptime

This coolant-through tooling system replacement for the gang plate on a Swiss-type machine can save hours of spindle downtime per day as well as increase tool life and enhance chip control.

#techbrief