Double-Spindle Machining Center Offers High Rigidity

GMTA’s Rasoma DSP 450-2 double-spindle machining center’s thermal stability is enhanced by cooled motor spindles and the rapid traverse on these centers ranges up to 60 m/min. at high acceleration.

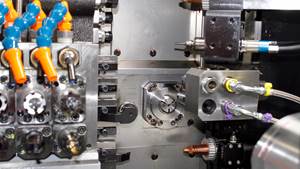

SS207-5AX Swiss-Type CNC Lathe Combines Welding and Cutting

Tsugami’s SS207-5AX Swiss-type CNC lathe with two fully integrated SPI lasers, one for laser cutting and one for welding, is the first LaserSwiss to incorporate laser welding.

EHC125300 CNC Horizontal Lathe Handles Large Parts

SMTCL’s EHC125300 is a high precision CNC horizontal lathe featuring swing over the bed of 1250 mm or 49” that can handle parts up to 3 m in length or 118 inches.

#horizontal-and-vertical-lathes

SL8-II Slant Bed CNC lathe is Designed to be User-Friendly

Milltronics USA Inc.’s SL8-II slant bed CNC lathe is designed to be user-friendly and features a Series 9000 CNC control that can be programmed either conversationally or with industry standard G & M codes.

Locked and Loaded for Further Growth in Firearms Production

Even with a strong and varied manufacturing background, it wasn’t until a few years ago that this father and son team found its way into the manufacture of weaponry components. Nonetheless, business is booming.

Shop/Supplier Relationship is Critical to Success

A quartet of CNC machines supplied by T W Ward CNC Machinery Ltd. play a key role in enabling Cosmopolitan Engineering to consistently be a supplier of parts of all sizes and in all metals, including tool steels and titanium, for more than 30 years.

Programming Considerations for Inverted Vertical Turning

Since its inception, the self-loading/unloading design of inverted vertical turning machines has evolved to include multitasking operations that augment its original task of turning. This article looks at ways to optimize the programming of these machines and to take advantage of the multiple operations available for workpiece processing.

Preparing for Lights-Out Production

As manufacturers face the challenges of reducing cost-per-part while meeting quality and delivery demands, adding a workerless third shift is a tantalizing possibility. It’s also a bit scary.

Accessories for Swiss Make a Big Difference

We recently published an article that revisited the state of the art in Swiss-type accessories. Often, these are at the heart of the successful application of Swiss machining because they allow for various applications.

Multitasking Represents a Trend for Growth

The need for turning shops to increase their capabilities by incorporating new technologies has allowed us to broaden our scope to include interesting topics such as multitasking machines. Read further for information about a shop that has added bar-fed mill-turn machines to better meet customer needs.