Corrosion Prevention: How to Avoid the Enemy of Metal Parts

This chemical reaction that is a constant, indiscriminate and costly enemy of metal parts is preventable, but intentional measures must be taken and become an essential process within a company’s walls.

#techbrief #basics

Producing high quality parts is a priority for any shop, especially in today’s highly competitive market. So, when an obstacle such as corrosion averts this goal, it is worth taking necessary steps to avoid it. This chemical reaction that is a constant, indiscriminate and costly enemy of metal parts is preventable, but intentional measures must be taken and become an essential process within a company’s walls.

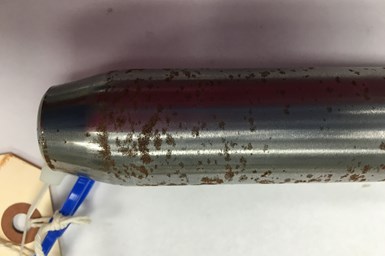

Usually, corrosion is the oxidation of metals in the presence of water or water vapor. The corrosion reaction between metals and oxygen is immediate and continuous, unless the corrosion cell perpetuating the reaction is stopped. Corrosion on metal is a result of oxidation — a molecular, destructive reaction between oxygen and a metal’s surface. While oxidation does not weaken metal, the surface disintegrates, forming a brittle film. Rust, however, does weaken metal and is a serious concern.

Featured Content

Creating a corrosion barrier is a common method implemented by manufacturers. This barrier can be formed by an organic (oil/wax) liquid coating (such as formulated wet films), aqueous dry film deposition or via packaging products that contain vapor (volatile) corrosion inhibitors (VCI).

VCI film is packaging that generally consists of polyethylene film or an engineered paper which has been impregnated with chemical formulations that are unique to each manufacturer. While the underlying formulations can vary significantly, the finished products all function similarly in that they release very low concentrations (typically in parts per ten-thousandth) of invisible corrosion-inhibiting vapors into the surrounding air. The vapor

Keep cleaning solutions and metalworking fluids clean to reduce or eliminate small metal particles that can linger on machined parts.

molecules subsequently condense onto exposed metal surfaces and form a molecular corrosion shield that can protect against rust and other forms of corrosion for up to five years and longer in some cases. When the VCI packaging is removed, all vapor corrosion-inhibiting molecules rapidly evaporate. This leaves the metal parts clean and ready for immediate use.

Besides using corrosion barriers throughout the manufacturing process, here are some other tips to help ensure corrosion-free metal parts, providing the highest quality product for customers. These tips were provided by Wayne Siefert, president, Green Packaging Inc.:

1. Production, inspection and packaging personnel should always wear gloves while handling metal parts because contaminants and acids present on human hands can cause and promote corrosion and rust.

2. Be sure that metal parts do not come in direct contact with wood pallets, corrugated boxes or untreated paper at any time during production, storage or shipment.

3. Parts must be clean, dry and free of fingerprints before packaging. Place parts in a wire basket to dry and use vibratory action or forced air that can dry parts more quickly when possible. Do not stack parts on top of each other until completely dry. Parts can corrode when stacked one on top of the other or when contacting each other in tote bins.

4. Parts should be clean and oil/coolant free before applying liquid/dry film corrosion inhibitor. Applying corrosion inhibitor over oil and coolants is generally not effective because oil and coolant films do not enable the corrosion inhibitors to make contact with the part surface.

5. For ocean transport or storage longer than 30 days, use a corrosion protection solution and a combination of VCI paper and a VCI bag for complete corrosion and rust prevention.

6. Do not place hot parts in the shipping package. Let the parts cool to the ambient room temperature before packaging.

7. When parts arrive at a customer’s facility, instruct the customer to keep VCI bags closed until parts reach ambient air temperature.

8. Keep cleaning solutions and metalworking fluids clean to reduce or eliminate small metal particles that can linger on machined parts.

9. Be sure to maintain solutions at the correct concentration.

10. If using water in your cutting or cleaning fluids, DI (deionized) water is recommended.

11. Keep metal parts away from industrial air contaminants such as exhaust from lift trucks and manufacturing, and heat treat areas because they are corrosive to metal.

12. Keep temperature in manufacturing and shipping areas constant. Every 10°C increase in temperature can double the corrosion rate.

13. Keep relative humidity in manufacturing and shipping areas constant and as low as possible. Fluctuations in humidity and temperature can cause condensation, which will promote and accelerate rust and corrosion.

14. Ship parts via the most direct method. Temperature cycling often occurs during transport through different climates. This can cause condensation on parts and subsequent corrosion.

About the Author

Charlie Pitarys serves as one of KYZEN'S technical experts supporting a global sales team and customer base. With over 30 years of cleaning process experience, Pitarys is the go-to guy for cleaning questions.

RELATED CONTENT

-

Caution: Bad word ahead – Corrosion!

As our membership grows, so does the shared technical information of our collective group. Educational article links, like this article on corrosion, are always available on our website.

-

Rust Season Is Here: Take Care of Your Precision-Machined Parts

To prevent corrosion from developing on the surfaces of freshly machined parts, it is crucial to create a barrier on the parts’ surfaces so moisture and oxygen don’t reach them.

-

Versatile Soft Jaw Introduces One-Size-Fits-All Technology

This soft jaw technology conforms to any part geometry and does not require removal from the machine tool when switching to a new job. It also saves shops setup and machining time, energy, and cost involved in the design and development of creating a custom soft jaw.