Metalcutting Fluids Fight Microbial Contamination

Metalcutting fluids have always been vulnerable to microbial contamination, but new formulations address that problem.

#metalworkingfluids

Insight into Minimum Quantity Lubrication

This article is the result of an interview with Dr. Radu Pavel, who is chief technology officer at TechSolve Inc. and Optis LLC. He focuses on process design and optimization as well process monitoring and control.

#metalworkingfluids

A Foundation for Minimum Quantity Lubrication

MQL can provide significant savings and improved performance in the right applications. Here are some important considerations when looking at this technology.

#metalworkingfluids

Shop Cleans up Oil Room with Storage and Dispensing System

Last year, DuPage Machine Products replaced the sprawling, inefficient and unorganized 55-gallon drums with the centralized storage and dispensing system from The IFH Group.

#metalworkingfluids

Metalworking Fluids Address Increasing Demands

This line of metal removal emulsion technology products offers end users of metalworking fluids a defined selection of choices to suit their specific needs for process efficiency and lower total cost of ownership.

#metalworkingfluids

Proper Fluid Management Improves Longevity, Part Quality

Basic maintenance practices listed here can improve a fluid’s longevity, shop environment and part quality.

#metalworkingfluids

Remove Tramp Oil before it Causes Damage

These oils can end up in the coolant sump and contaminate the metalworking fluid.

#metalworkingfluids

Low Foam Technology Solves Production Problems

QualiChem brought in its Xtreme Cut 250C coolant to get rid of a foaming issue in a coolant delivery system.

#metalworkingfluids

A Guide to Metalworking Fluids

The oils, coolants and lubricants used in metalworking shops are often overlooked as an opportunity to improve process efficiencies.

#metalworkingfluids

Maximize Coolant Life with Efficient Tramp Oil Removal

Increased demands for high surface finish and close part tolerance create a greater need for manufacturers to purify coolants that are constantly being cycled through precision machinery.

#metalworkingfluids

Water-Glycol Hydraulic Fluid Resists Fire

Quaker Chemical’s Quintolubric 702-46 RD fire-resistant hydraulic fluid is a water-glycol formulation designed to increase safety, reduce maintenance and extend product life.

#metalworkingfluids

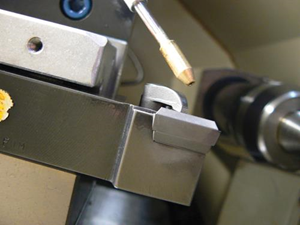

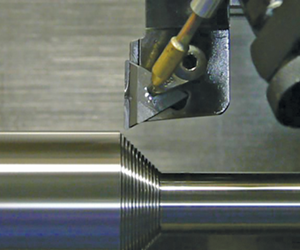

External-Coolant Live Tooling Heads Get an Upgrade

One of the most important aspects of effective coolant usage is precise delivery to where it is needed in the cut.

#metalworkingfluids

Efficient Use of Metalworking Fluids

As shops continue to reach for new ways to achieve higher efficiencies, they commonly turn to improved processes, new equipment and automation. But one point of attack—more effective use of metalworking fluids—often goes unaddressed.

#metalworkingfluids

The Changing Role of Metalworking Fluids

Every aspect of the metalworking process is under scrutiny to reduce costs and improve efficiencies, including the use of metalworking fluids.

#metalworkingfluids

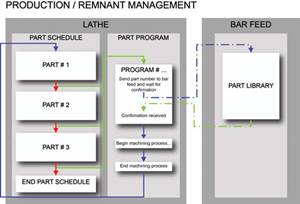

Shopfloor Data and the Future of Manufacturing

Redundancy is far too common in many areas of life. Standardized processes that streamline production might be the perfect solution.

#metalworkingfluids

Tooling Tips for Exotics

While exotic materials typically provide improved wear characteristics and better service life in the final product, they can present particular challenges during machining.

#metalworkingfluids #workforcedevelopment #basics

Considerations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.

#metalworkingfluids

Magnetic Filtration Leads to Premier Finish

Magnetic filtration can be used in almost any environment where ferrous and paramagnetic contamination of a liquid is a problem.

#metalworkingfluids

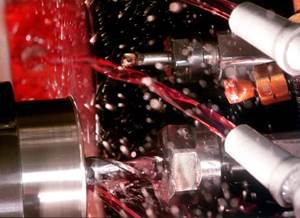

Technologies for Chip and Coolant Management

To the casual observer, removing the chips created during a metalworking manufacturing process may seem about as complicated as emptying a waste basket.

#metalworkingfluids

Sustainable Metalworking with Minimum Quantity Lubrication

Companies involved in metalworking operations have an obligation to develop sustainable manufacturing solutions.

#metalworkingfluids