Improve the Shopfloor Environment

Any form of pollution in the shop environment is potentially dangerous to personnel.

#metalworkingfluids

Automation, Parts Cleaning and Coolant Filtration in One System

As bids came in for new systems for plant automation, parts cleaning and deburring, as well as centralized coolant filtration systems for the company's engine block and head production line, Cummins found that Dürr Ecoclean could handle all three tasks.

#metalworkingfluids #Industry40

Cutting Tools for Titanium, Aluminum and Composite Aerospace Components

The company offers a range of Cyclo Cut cutting tools and Cyclo Cool metalworking fluids designed and blended for all aspects of aerospace machining.

#metalworkingfluids

Integrated Solutions for Chip Removal and Fluid Filtration

Shops can easily view chips simply as waste, hardly giving a second thought to the disposal process and the potential related savings. By keeping an eye on the waste and choosing the most efficient methods of chip disposal, a shop can easily add to the bottom line through substantial savings.

#metalworkingfluids #workforcedevelopment

It's Only A Number

A person’s age is often said to be only a number, with overall health and fitness being the truly significant measures. Cutting fluids, like all industrial lubricants, should be held to the same standards—it really is condition that matters. By focusing on that philosophy, a shop can achieve immediate, sustainable cost savings.

#metalworkingfluids

Successful Untended Operation

Machine tool accessories can make or break untended operation.

#metalworkingfluids

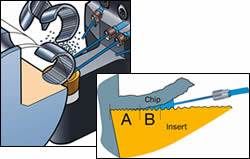

Chip Control With Coolant

Directing high pressure coolant under the chip in turning applications can improve cutting rates, tool life and surface finish.

#metalworkingfluids

Cutting-Edge Cutting Oil

This shop sought after a lubricant that would eliminate the drawbacks of oil, upgrade the overall quality of production and save money by reducing tool changes. It found Picocut Code Blue by Pico Chemical Corporation as the answer to its problems. This oil was developed in response to customers’ requests for a chlorine-free oil that can replace older technology products, but at the same time, meet the need for longer tool life, higher production speeds and improved finishes.

#metalworkingfluids

A Cool Way To Cool

With increasing regulations on handling and use of metalworking fluids, the industry needs to look at other options to help resolve the contradictions between the need for cooling lubrication and the requirements for cleaner, safer technology.

#metalworkingfluids

Efficient Operation With High-Pressure Coolant

Manufacturers spend millions of dollars on liquid coolants each year to help machine tools cut metal more efficiently. In many cases, however, the effect of this coolant could be greatly enhanced—in some applications by 100 percent or more—by using a high-pressure coolant delivery system.

#metalworkingfluids

This Filtration System Takes The Cake

For chip removal and coolant filtration in many CNC machining operations, capital cost and proven efficiency still make disposable media designs the common choice. Permanent media chip removal and coolant filtration systems, however, have quickly become a viable option for helping to lower operating and maintenance costs in certain applications. In high-production operations, these systems can increase tooling life and coolant life and reduce nozzle clogging. The systems also are environmentally beneficial and provide cost savings related to media replacement and operator involvement.

#metalworkingfluids

Synthetic Coolant Shines In Shop-Wide Applications

TNS Machining (Muskego, Wisconsin) is both a prototype and production machining job shop. After working in the machining industry for many years, Thomas Rowinski, Jr. and his sons started this business in 1981 because they wanted to provide customers with specialized precision machined parts.

#metalworkingfluids

Coolant Filter Requires No Replaceable Elements

This coolant filter back flushes the trapped particles away from the permanent filtering element to restore its effectiveness. The operating principle is similar to a backyard swimming pool.

#metalworkingfluids

Coolant-Through Turning Toolholders Deliver Increased Performance And Tool Life

It should be obvious to anyone who has ever washed a driveway or patio with a garden hose: For the best results, you must keep the stream of water precisely where it's needed. The same principle applies to delivering coolant to the cutting zone.

#metalworkingfluids

Pump/Filter Unit Eliminates Sump Clogging Problems

Because of the volume of relatively small parts running steadily in the machine, one shop's concentration of small chips and fines in the oil increased rapidly. To address the problem, the company purchased a pump/filter unit.

#metalworkingfluids

The Science Of High-Pressure Coolant

High-pressure coolant is the new 'hot' technology, with approximately a 500 percent increase in use in the last 10 years.

#metalworkingfluids

Vegetable Oil Improves Machining Of Medical Devices

Production management at this shop speculated that many of the materials used and operations performed might benefit from the higher level of lubricity characteristic of vegetable oils. Any consequent additional capacity and tool life would be a plus.

#metalworkingfluids