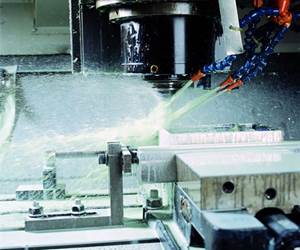

Improving Process Efficiency with Metalworking Fluids

Using the right oils, coolants and lubricants can help a shop optimize machining processes, but there are many factors to weigh when choosing metalworking fluids.

#metalworkingfluids

Low-Foaming Metalworking Fluids Offer Corrosion Protection

Tech Cool 35058 and Tech Cool 35037 join Chemetall's line of metalworking fluids.

#metalworkingfluids

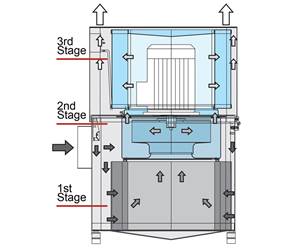

Mist Collector Removes Harmful Oil Mist and Particles

The mist collector filters and removes oil, coolant and water soluble mist from the air around enclosed machinery.

#metalworkingfluids

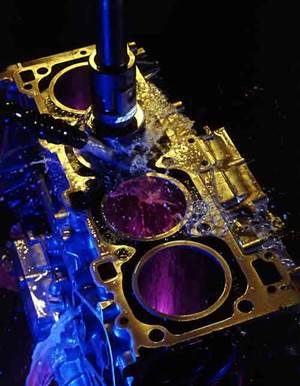

Masterall 1300 Coolant Used in High Pressure Applications

Etna Products’ Masterall 1300 is a water miscible, medium oil, low foaming semi-synthetic fluid designed for high pressure coolant applications.

#metalworkingfluids

Dryness is the Name of the Game When Wringing Chips

Wringmaster Systems has combined a live bottom unit and a chip blower, reducing chip contact with expensive components while increasing dryness and recovering even more cutting fluid.

#metalworkingfluids #techbrief

FA 70 Ultrafine Filtration Technology Used for Regrinding

The Vomat FA 70 standalone filtration system has a maximum filtration capacity of 70 L per minute and provides clean oil in NAS 9 quality over a long service period.

#metalworkingfluids

Handte Oil Expert Mist Collector Removes Ultra-Fine Mists

Camfil APC’s Handte Oil Expert eliminates the ongoing housekeeping expenses required to remove oil from heating and cooling equipment, other machinery and workplace surfaces.

#metalworkingfluids

Why Honing Oils Matter

Like any metalworking process, honing relies on a systemized approach of components working in concert to deliver optimized results. Honing oil is one of these critical components, and this article examines the role it plays in a successful honing operation.

#basics #metalworkingfluids

Filtration Systems Ensure a Continuous Clean-Oil Supply

Vomat fine filtration systems filter to NAS 7 (3-5 microns), operate in full-flow mode and separate dirty and clean oil while the system filters and cleans the machine, meaning that the backflush cycle is initiated automatically for each individual filter element.

#metalworkingfluids

1/4 NPT No Drip Atomizing Spray Nozzle Covers 360 Degrees

Exair’s 1/4 NPT No Drip internal mix 360-degree hollow circular pattern atomizing spray nozzle can provide a smooth, even coating on the inside diameter of a pipe or similar ductwork and is also effective for operations where mist over a broad area is needed.

#metalworkingfluids

Sump Cleaner Transport Base Handles Coolant in Large Plants

Cecor’s CB6 Sump Shark sump cleaner transport base can move a sump cleaner through a plant between collection, treatment or disposal, and off the truck an operator can use controls to maneuver the unit into tight spots and next to machine tools.

#metalworkingfluids

Lubrication Coating System Requires Minimal Intervention

Layton Technologies’ lubrication coating system is an ATEX approved design with vapor detection, flame detection, fire protection and suppression system that includes ultrasonic agitation and subsurface jets to agitate the fluid when parts are being processed.

#metalworkingfluids

Fluid Reclamation Machine Restores Metalworking Fluids

Eriez HydroFlow’s SumpDoc portable inline fluid reclamation machine’s design has been updated to be simple to operate and small and lightweight enough to allow an operator to push it quickly and easily from location to location.

#metalworkingfluids

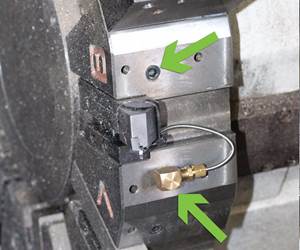

VR8 High Pressure Coolant System Extends Machine Tool Life

MP Systems’ VR8 variable volume high pressure coolant system (HPCS) can extend machine tool life, improve part quality, and reduce cycle time, and is part of a line of HPCSs the company launched in late 2016.

#metalworkingfluids

Filtration Technology Separates Dirty and Clean Oil

Vomat’s full flow filtration technology separates dirty and clean oil and provides cleaned cooling lubricants to NAS 7 (3-5 μm) standards, allowing coolant to remain longer in the system than in conventional filter systems.

#metalworkingfluids

Coolant Systems Offer Alternative to Edge-Type Filtration

Eriez HydroFlow’s Coolant SuperFiltration systems remove particles down to 3-micron nominal from cutting fluid while maintaining a stable fluid temperature and offer an alternative to edge-type filtration in oil applications.

#metalworkingfluids

Therma Quenching Oils Provide Efficient Use

Condat’s Therma range of quenching oils have evolved in order to comply with requirements and regulations related to the use of oils, with the products formulated exclusively from Group III, highly refined base oils ensuring safer and more efficient use.

#metalworkingfluids

Getting the Most from MQL

Here's a broad view of minimum quantity lubrication along with a closer look at using MQL in turning applications.

#metalworkingfluids

Minimum Quantity Lubrication isn’t for Every Application

Although the benefits of MQL are tangible for many applications such as turning, milling, drilling, and related operations, the technology is not well suited for all applications.

#metalworkingfluids

Oil/Coolant Mist Collector Addresses Efficiency Challenges

These oil/coolant mist collectors can contribute to employee safety and a better work environment all around.

#metalworkingfluids