A Multi-Spindle and Swiss Combination

At the recently completed EMO show in Hannover, Germany, the world’s machine tool and metalworking industry put on the biggest exposition on earth.

Custom Turning with Only Two Operators

With only two people, the shop provides complete CNC mill-turn services plus CNC milling, CNC turning, inspection, prototyping, production and assembly.

Moving Up to CNC for Smaller Lot Sizes

This small shop has a large presence. CNC is playing a significant role in the company’s ability to deliver parts for the big stage.

Saving Lives with a Net

Every day, metalworking manufacturers contribute to the general and specific welfare of our nation’s economy by adding value and creating wealth. This New Hampshire shop has the added distinction of helping save the lives of our combat troops.

Taking a Turn Toward Production Flexibility

Swiss-type screw machines provide unparalleled machining capabilities when it comes to processing small, detailed parts.

Attain Consistent Roundness and Concentricity Readings

The CNC Swiss-type lathe is finding an increasingly large market as non-traditional Swiss shops find its production advantages for small, precise and complex workpieces.

Manufacturer Stays True to 106-Year-Old Niche

Finding a niche and sticking to it sounds like common sense. Sometimes, however, companies get distracted, even bored, with a niche. That’s never been a problem for the Fischer family.

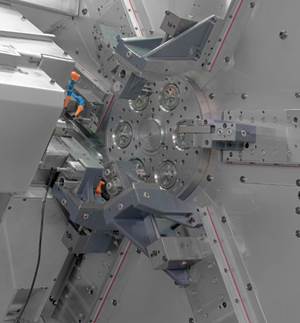

Beefed-Up Backworking on New CNC Multi-Spindle

This CNC multi-spindle automatic lathe includes a quillstock with six tool carriers and one counter spindle opposite the main six-spindle drum, allowing machining of complex workpieces in a single process.

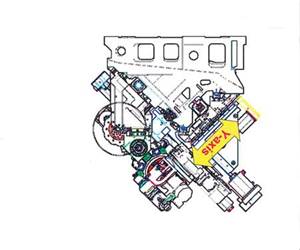

The Evolution of the Y Axis on Turn-Mill Machines

Introduced to the turn-mill machine tool design in about 1996, the Y axis was first used on a single-spindle, mill-turn lathe with a subspindle. The idea of a Y axis on a CNC originated from the quality limitation of polar interpolation and the difficulty in programming, not from electronic advances in controls or servomotor technology as one might commonly think.