Faster Change-Overs Allow Focus On Machining

A creative Midwestern shop shows that its productivity edge runs all the way down to its relationships with vendor partners. With the right clamping and centering device, the company has been able to reduce workpiece change-over times by as much as 50 percent while improving rigidity and precision.

Direct Drive Rotary System Reduces Cycle Time

In the early 1990s, Mr. Langlois decided to set up a shop specializing in close-tolerance aerospace parts. A friend of his recommended that he consider a colleted-spindle turning machine and suggested that he look into Hardinge lathes. Mr. Langlois purchased a used Hardinge HNC lathe and began making aircraft landing gear bushings.

Specialty Company Knows Its Collets

For almost 3 years Mr. Bouchard struggled with a machine application designed to produce life-critical airbag parts for Arrow Machine’s primary client in the automotive industry. With the help of RH Collets, a manufacturer of specialty workholding and related components for Hydromats and other machinery, Mr. Bouchard is solving the problem—not with one new part but with a series of solutions.

Successful Untended Operation

Machine tool accessories can make or break untended operation.

#metalworkingfluids

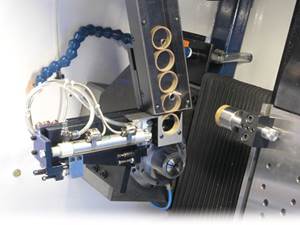

Automation In A Production Shop

Production turning automation is the beneficiary of increasingly powerful design and application tools. This makes it much easier to create automation that fits the application.

Reestablishing A Name In Bar Feeders

To keep its well known line at the forefront of the minds of those in the market for a bar feeder, this company completely redesigned its product. Features such as a see-through cover and Direct Connect programming through the machine tool's CNC demonstrate the results of this focused effort.

Bar Feeders And Workpiece Surface Finish

Quality surface finish of a part is not only dependent on the turning machine itself, but also on the barstock loading and support system. The bar feed system becomes critical to the surface finish outcome by enabling the turning machine to create the desired finish and/or by protecting the existing finish.

The Change To Quick-Change Collets

Quick-change collets can improve production times and accuracy while alleviating any change-over issues typically associated with standard collets.

Hold On With Vacuum Clamping

Because of the possibility of workpiece deformation, clamping using three-jaw chucks is not always suitable for final machining. In cases where tight machining tolerances must be upheld, this Danish cutting specialist relies on vacuum clamping technology to hold its parts.

Drafting New Players For Swiss Precision

Consistent operations play a big part in attaining high productivity. That’s why, as a shop grows (as this Swiss shop has), it should look to add machines—and employees—that complement each other.