Walter’s Drilling Grade for Drilling Aluminum

This grade is designed to enable reliable chip removal due to its smooth surface with a reduced tendency toward adhesion and buildup on the cutting edge, thereby increasing process reliability and wear resistance.

Tungaloy CBN Inserts for Threading Hardened Parts

The inserts both feature a brazed CBN tip which is designed to provide a cutting edge with a balanced combination of wear and fracture resistance for withstanding continuous and heavy cutting loads.

Ingersoll NanoFeed Indexable Insert for Small Parts

The 20-degree, high-feed indexable insert design can replace smaller diameter solid carbide end mills in many applications and is said to reduce cycle times, increase productivity and help reduce solid carbide usage.

Walter Cut DX18 Inserts for Grooving, Parting Off

Insert’s new geometries are designed to improve tool life, process reliability and cycle times.

Tungaloy’s PCD Turning Inserts for Improved Chip Control

The inserts feature an all-purpose NS chipbreaker for nonferrous applications.

Inovatools’ TSC Milling Cutters for High Cutting Volumes

The company says the machine kinematics and drives can withstand high speeds and dynamic load changes.

Sandvik Coromant Solid Carbide Drill for ISO P Steels

Upgraded CoroDrill 860-PM assortment is designed to make drilling steel faster and more efficient.

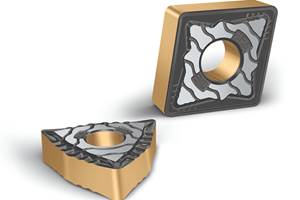

Ceratizit Standard Insert Grades for Optimized Steel Turning

The inserts are engineered for increased productivity and feature advanced substrates, geometries and Ceratizit’s Dragonskin multilayer coating for lower heat and less tool wear.

Walter Tiger-tec Gold Inserts for Tough Steel Turning Applications

A highly textured MT-TiCN layer is said to reduce flank face wear and increases toughness due to its multilayered elastic structure.

Niagara Cutters Redesigned to Reduce Power Consumption

Upgrade also includes aluminum nonferrous PVD coating which is said to reduce friction and built-up material on the cutting edge to improve workpiece surface finish and increase tool life.