Machining Center for Small Workpieces

Here’s a different approach to a micromachining center--a machining strategy developed around interpolation, allowing machining operations to benefit from the dynamic control of the worktable while reducing the number of tools needed.

#micromachining

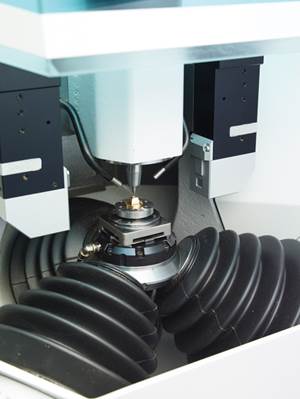

Purpose Built Micromachining Center

In metalworking, it is rare to find new approaches to well-established technologies; usually new developments are major or minor upgrades to known elements. This micromachining center is rewriting the rulebook.

#micromachining

Small Machines for Micromachining

Proper tooling and machining options are critical in developing an optimized plan for micromachining.

#micromachining

Accuracy Helps Swiss Watches Keep Perfect Time

Production engineering solutions required by many Swiss watchmakers are already installed in their CNC machines when they buy them.

#micromachining

Applying Waterjet Micromachining

Scientists are deeply involved in exploring the frontier of micro-abrasive waterjet technology.

#micromachining

Micro-Boring Tool Calms ‘Perfect Storm’ for Medical Parts Fabricator

In one of its first commercial applications, an Ingersoll micro-boring tool has brought process stability to a machining application that the user describes as a “perfect storm.”

#micromachining

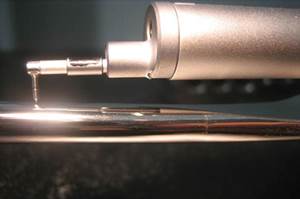

Cutting a Micron at a Time

When the task is to remove very small amounts of material, this process may be the answer.

#micromachining

The Smaller Side of Technology

Working in the manufacturing field, I find that my personal conversations with friends and family often lead to the amazing technology I see on a regular basis.

#micromachining

Tooling Up for Micromachining

Choosing the right tools and matching them to the correct operations and process techniques for micromachining applications is critical to success in this burgeoning market.

#micromachining

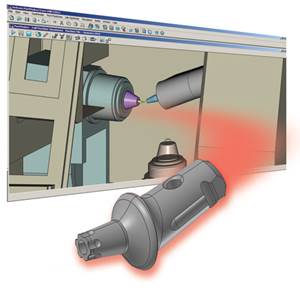

CAM Software Considerations for Bar-Fed Mills

Time will tell, but increasingly, there is evidence that points to the fact that bar-fed mills could well represent the future of complex, small parts manufacturing.

#micromachining

Small Parts Have Big Impact

Advanced micromachining capabilities have had a monumental effect on the way parts are produced. But as parts continue to get smaller, complexities increase, as do corresponding tolerance requirements.

#micromachining

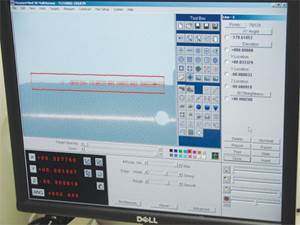

Micro Measuring

Making micro sized parts is one thing; measuring them is another.

#micromachining

Micro-Drilling Calls for Considerations

“Tiny” usually comes to mind when the term “micro” is used. So it is easy to assume that micromachining equates to very small parts found in the medical and electronics manufacturing industries.

#micromachining

Pigging Out: High Feed Machining Techniques For Small Cutters

Small machining applications—those relying upon tool diameters smaller than 2. 0 mm—are continuing to grow based upon both consumer demand and developing machining technology. It’s apparent that the trend to produce ever-tinier electronic goods will continue (smaller cell phones, minute keyboards, plastic ear buds, and so on); all require small and precise mold insert creation.

#micromachining

High Speed Spindles For Swiss Machining

This article discusses the use of high-speed spindles in Swiss machining applications. Sufficient rotational speed is necessary to take advantage of tooling materials in small diameter cutters.

#micromachining

Could You Repeat That?

The extremely small, complex devices used in procedures to restore hearing loss require high-precision, tight-tolerance production. This company has found the right combination of machine tool technology and quality assurance to make it work.

#micromachining

Unique Business Coincides With Unique Customers

Using Rollomatic grinding machines, as well as other grinding machines, this company manufactures micro-cutting tools ranging in size from 0.0002 inch to 0.125 inch.

#micromachining

Making It Big In Small Parts

This New Hampshire manufacturer is an expert in manufacturing small, complex parts. Having a niche is one solid strategy for survival, but it takes dedication, focus and technology to pull it off.

#micromachining

Medical Machining: Speed And Accuracy Win Orders

To handle the steady flow of incoming orders, this company has prepared itself by building facilities and purchasing equipment that are able to complete its jobs quickly and efficiently.

#micromachining

Choosing Advanced Tooling For Swiss Machining

The right tools for Swiss machines can boost throughput and improve the quality of finished parts. For example, switching from brazed carbide parting tools to more wear resistant coated carbide inserts with sharper edges reduced cycle time on an automotive fluid connector from 11 seconds to just 5 seconds.

#micromachining