PM Blog

It’s a Moving Experience, Part 1

Moving after 75 years: Lessons from W.H. Bagshaw’s big leap.

Read MoreCraftsman Cribsheet No. 146: Powder Bed Printing for the Shop

Properties of powder bed printing metals.

Read MoreKey Takeaways from the PMPA 2025 Annual Meeting

Discover how the PMPA 2025 Annual Meeting elevated the industry through high-impact networking and expert insights.

Read MorePiezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

Read MorePrecision Machining Index Climbs Into Expansion

The GBI: Precision Machining finally broke past the 50 mark with strong October results.

Read MoreCutting Tool Considerations for Hydraulic Port Machining

Indexable insert cutting tools can boost the efficiency of port machining processes by creating multiple features in a single operation.

Read MoreStaffing and Workforce Development Ideas

Here, industry experts suggest ways to bolster your staff and their talents through onboarding to upskilling.

Read MoreConnected Media Brands Offer Cross-Disciplinary Insight

Gardner Business Media’s new Manufacturing Connected platform leverages its various industry brands to bring manufacturing leaders actionable insights about trends and new technologies in one spot.

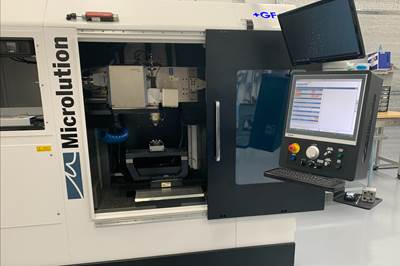

Read MoreWhere Micro-Laser Machining Is the Focus

A company that was once a consulting firm has become a successful micro-laser machine shop producing complex parts and features that most traditional CNC shops cannot machine.

WatchManufacturing Scheduling System Focuses on the Now

Improving on-time delivery can happen by prioritizing what needs to happen first, not what job is due first. Among other capabilities, the Production Flow Manufacturing concept can identify situations in which a job with a later due date is actually more urgent.

Read MoreMoving From Ideas to Action

Do you invest, transition, tolerate or eliminate your team’s proposed ideas? Here is a structured method for evaluation.

Read MoreBuilding a Culture of Caring

In the words of one Michigan machine shop’s president, it starts by identifying those who “give a sh*t.”

Read More