Production Machining’s April 2023 News Highlights

Edited by Angela Osborne

Production Machining’s April 2023 news highlights include a special honor for a GBM stalwart, reshoring news, new technician training, workforce development funding and more.

The Control’s Role in Machining Complex Parts

Edited by Lori Beckman

This company that produces medical implants finds value in the CNC for its turn-mill equipment that helps speed setups and simplify programming when producing intricate parts complete.

Video: Why a Production Machine Shop Started a Baseball Bat Company

By: Derek Korn

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

#horizontal-and-vertical-lathes #basics

PMTS 2023 Product Preview: Swiss-Types

Edited by Angela Osborne

Learn about some of the latest Swiss-type solutions that will be on display at PMTS 2023.

Choosing the Right Machine for Turned and Milled Medical Parts

The medical market is known for exceptionally tight tolerances and difficult materials, which means that selecting the proper machine is necessary to ensure a job is profitable.

PMTS 2023 Product Preview: Shop Management Software

Edited by Angela Osborne

Learn about some of the latest shop management software solutions that will be on display at PMTS 2023.

Parts Cleaning is Now More Important Than Ever

By: Derek Korn

Co-located at the Precision Machining Technology Show, the Parts Cleaning Conference enables you to learn about the latest in parts cleaning technology.

#PMTS

CMM Systems Must Comply With FDA Validation

By: Scott Lowen, Software Product Manager, ZEISS Industrial Quality Solutions

Validation requirements set by the U.S. Food and Drug Administration can be tricky to satisfy. The following recommendations will lead to validation of both the CMM system and the inspection process.

#columns

Educational Offerings at PMTS

By: Derek Korn

Technical presentations and on-the-show-floor, booth demonstrations can lead you to discover new ideas to help your shop become more efficient and profitable.

#PMTS #workforcedevelopment

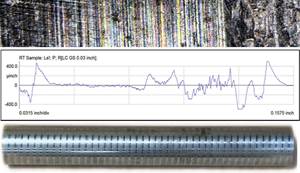

Craftsman Cribsheet No. 114: Factors Influencing Machined Surface Finish in Our Shops

By: Miles Free

Surface finish is the result of our machining process on raw materials.

#pmpa

PMTS 2023 Product Preview: Parts Cleaning

Edited by Angela Osborne

Learn about some of the latest parts cleaning solutions that will be on display at PMTS 2023.

Software Controls Chip Breaking in Thread Turning Operations

By: Lori Beckman

This cutting tool manufacturer has developed a software module for chip control of thread turning operations in virtually any CNC lathe, even for older machines, using specific tooling and software.

#techbrief #horizontal-and-vertical-lathes

Get to Know the PMPA at PMTS 2023

By: Derek Korn

The Precision Machining Technology Show provides the chance to see what membership in the Precision Machined Products Association offers at the association’s co-located National Technical Conference.

#PMTS #basics

Roles of Women in Manufacturing Series: Machinists Julia Dister and Sarah Grieve

By: Carli Kistler-Miller

Julia and Sarah share their journeys to becoming machinists and give advice to anyone seeking a career in manufacturing.

#pmpa

Where Did the Employees Go?

By: Jeffrey L. Reinert, President, Schütte Corp.

As many employees have exited the workforce, manufacturers are left with doing more with fewer people. Therefore, management must work hard to attract new employees and retain the good ones.

#columns

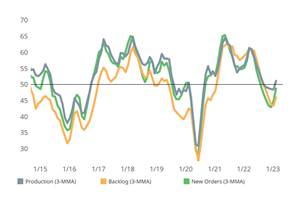

Gardner Business Index: Precision Machining February 2023

By: Jan Schafer

In February, GBI: Precision Machining component activity generally changed direction in a good way.

#columns

Take the PMTS Tech Challenge Tour, Participate in PM’s Custom Bat Contest

By: Derek Korn

You come to the Precision Machining Technology Show to discover new machining technology. But, you also could easily walk away with $1,500 or have a chance to create your own custom wooden baseball bat.

#PMTS

Production Machining’s March 2023 News Highlights

Edited by Angela Osborne

Production Machining’s March 2023 news highlights include PM Emerging Leaders nominations, company accolades, community involvement, expanding distribution networks and more.

Parts Cleaning Sector Shifts Energy Toward Regulatory Changes

By: Lori Beckman

With changes in EPA regulations regarding the use of some popular cleaning fluids, cleaning suppliers and end users are readjusting business strategies and/or cleaning processes to meet new requirements.

How Important Is the Look of Your Machine Tools?

By: Derek Korn

Performance comes first, but there is value in equipment having a modern appearance, especially in terms of attracting potential young employees and engaging customers.

#columns