Precision Machining Technology Review June 2023: Automation & Robots

Edited by Angela Osborne

Production Machining’s June 2023 showcase includes some of the latest automation technology from LNS, Midaco, Lexair, New Scale Robotics and Euroline.

CAM-Driven Lathe Questions

By: Michael Huggett, National Sales Director, Index Corp.

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Cutting Tool Considerations for Hydraulic Port Machining

Edited by Derek Korn

Indexable insert cutting tools can boost the efficiency of port machining processes by creating multiple features in a single operation.

#techbrief

Gardner Business Index: Precision Machining May 2023

By: Jan Schafer

The Gardner Business Index: Precision Machining May 2023 indicates components expanding and contracting nearly evenly split.

#columns

Production Machining’s June 2023 News Highlights

Edited by Angela Osborne

Production Machining’s June 2023 news highlights include a motorsports partnership, company acquisition, supply chain partnership, new technical center and leadership, as well as a helpful materials guide.

Adding Additive Manufacturing to a CNC Machine Shop

By: Lori Beckman

With many types of metal and polymer 3D printing methods available, it might be difficult to identify the type that could be best implemented in your shop. Here is a rundown of these 3D printing processes along with how each can be used together effectively in a CNC machine shop.

#additive

The People Part of PMTS

By: Derek Korn

The Precision Machining Technology Show is a great example of discovering ways shopfloor employees can become more efficient, thereby helping shops become more profitable.

#columns #PMTS

Cold-Drawn Steel Barstock: How It Is Manufactured, Benefits to Your Shop

By: Miles Free

Understanding the benefits provided by cold-drawn steel barstock can help you optimize the work you quote by maximizing benefits to your manufacturing process and customer.

#pmpa

Data Matrix Codes Offer Cutting Tool Traceability

Edited by Lori Beckman

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

#techbrief

Craftsman Cribsheet No.115: Paint Your Edge to Gain an Edge!

By: David Wynn, Technical Services Manager, PMPA, Precision Machined Products Association

Kindergarten skills for the shop. Do you color your inserts?

#pmpa

Roles of Women in Manufacturing Series: Human Resources — Brenda Diehl and Diane Ferrera

By: Carli Kistler-Miller

Two women share their journeys to manufacturing and human resources, and give advice to anyone seeking a career in manufacturing.

#pmpa

How Incredible Machining Companies Predict the Future

By: Matthew Kirchner

An Incredible Precision Machining company measures its future business performance in real-time, using complex algorithms, predictive analytics, smart technology and leveraging artificial intelligence and machining learning.

#columns

Zoller Event Shines Lights on Shopfloor Connectivity

By: Lori Beckman

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

#Industry40

Markets Served — Who Knew?

By: Miles Free

PMPA members shared the markets they served in 2022. The top 5 may surprise you.

#pmpa

Production Machining’s May 2023 News Highlights

Edited by Angela Osborne

Production Machining’s May 2023 news highlights include new company and industry leadership, parts cleaning programs, business expansions and more.

Workholding Facilitates Fast Changeovers for Robotic Surface Finishing Systems Manufacturer

By: Frank Burke, Owner, Burke & Towner, Ltd.

This manufacturer finds value in modular workholding technology to speed production of toolholders and other components used in its automated surface finishing systems.

In-Machine Probing Possibilities for VTLs

Edited by Derek Korn

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

#horizontal-and-vertical-lathes

Eastec 2023 Product Preview

Edited by Angela Osborne

Production Machining highlights some of the upcoming products that will be displayed at the Eastec manufacturing technology series event May 16-18, 2023, in West Springfield, Massachusetts.

Gardner Business Index: Precision Machining April 2023

By: Jan Schafer

The Gardner Business Index: Precision Machining carried into April the trend from March, moving from flat into contraction, landing at an index of 48.9.

#columns

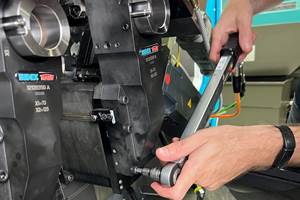

Repeatability and Rigidity Are Key for Quick-Change Swiss Tooling

By: Derek Korn

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

#techbrief